Clean agent fire extinguishers refilling service

Clean Agent Fire Extinguishers Refilling Service (All Types of Suppression Systems)

Refilling, Testing, and Recharging for FM-200, Novec™ 1230, CO₂ & Other Gas Suppression Systems

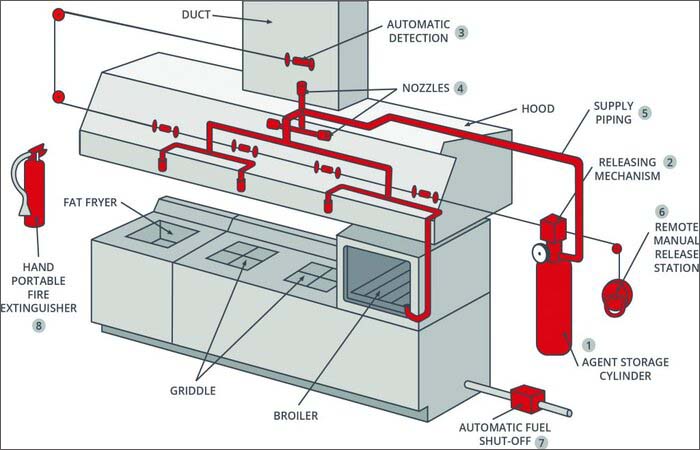

Fire Engineering Technology is India’s leading provider of clean agent fire extinguisher refilling and recharging services for all types of gaseous fire suppression systems including FM-200 (HFC-227ea), Novec™ 1230 (FK-5-1-12), CO₂, Inergen, and Argonite systems.

We specialize in high-precision refilling, hydro-testing, pressure integrity checks, and commissioning support, ensuring your suppression systems remain fully charged, compliant, and ready for immediate response.

Our services meet NFPA 2001, ISO 14520, and BIS standards for clean agent and gas suppression systems.

⚙️ Why Refilling Is Essential for Clean Agent Fire Suppression Systems

Over time or after a system discharge, the suppression cylinders lose pressure or become partially depleted. Even minor pressure loss can affect performance and fail compliance standards.

Regular refilling and inspection ensure:

-

Proper agent concentration

-

Safe and reliable discharge in emergencies

-

System compliance with NFPA & local codes

-

Extended system life and efficiency

Fire Engineering Technology provides on-site or factory-based refilling with advanced tools and certified technicians.

🧯 We Refill & Service All Major Clean Agent Systems

🔹 1. FM-200 (HFC-227ea) Systems

-

Refilling & pressure testing

-

Agent purity verification

-

Compatible with Kidde, Tyco, Ceasefire, Minimax, and other brands

-

Ideal for data centers, control rooms, and server areas

🔹 2. Novec™ 1230 (FK-5-1-12) Systems

-

Sustainable clean agent with zero ODP and GWP < 1

-

Refilling and re-commissioning for total flooding & modular systems

-

Used in IT rooms, electrical panels, BESS, and healthcare

🔹 3. CO₂ Suppression Systems

-

Refilling of high-pressure (HP) & low-pressure (LP) cylinders

-

Hydro-testing and leak testing

-

Suitable for paint booths, turbine rooms, transformers, and machine enclosures

🔹 4. Inergen (IG-541) / Argonite (IG-55) Systems

-

Refilling for inert gas blends

-

Cylinder pressure balancing and recalibration

-

Eco-safe and human-safe suppression gas service

🔹 5. Tube-Based & Modular Clean Agent Systems

-

Specialized refilling for pre-engineered & automatic tube-based systems

-

Ideal for electrical control panels, CNC machines, EV chargers, and ATMs

-

Available in Novec™ 1230, FM-200, or CO₂ configurations

🧩 Our Refilling Process

-

Cylinder Collection or On-Site Refilling

-

Cylinders are collected or refilled at the customer’s site (for modular/tube systems).

-

-

Agent Purity Check

-

We test and verify chemical purity using certified equipment.

-

-

Hydrostatic Pressure Testing

-

Cylinders undergo high-pressure testing as per BIS/ISO standards.

-

-

Refilling and Recharging

-

Cylinders are refilled to exact factory-specified weight and pressure.

-

-

Leak & Integrity Test

-

Pressure and valve sealing are verified under test conditions.

-

-

Reinstallation & Commissioning

-

System is reconnected, pressure-tested, and commissioned.

-

-

Documentation & Compliance Report

-

Complete refilling certificate and test documentation provided for audit compliance.

-

🏭 Industries We Serve

-

Data Centers & IT Facilities

-

Power Plants & Switchgear Rooms

-

CNC & Manufacturing Units

-

Hospitals & Laboratories

-

Commercial Buildings & Offices

-

Energy Storage (BESS) Systems

-

Airports, Railways & Metro Projects

-

Oil & Gas, Paint Booths & Industrial Plants

🌍 Why Choose Fire Engineering Technology

-

🔹 Certified Refilling Facility – NFPA 2001 & ISO 14520 compliant

-

🔹 Pan India Service Network – On-site support nationwide

-

🔹 Refilling for All Brands & Agents

-

🔹 Skilled Technicians with OEM-grade Tools

-

🔹 Environmentally Safe Handling & Recycling

-

🔹 AMC & Annual Maintenance Contracts available

We ensure every system is tested, verified, and re-certified before handover — maintaining 100% operational reliability and compliance.

FAQ — Clean Agent Fire Extinguishers Refilling Service (All Types Suppression)

This FAQ is designed for the Fire Engineering Technology website page dedicated to Clean Agent Fire Extinguisher Refilling & Recharging Services. It includes FAQ content and JSON-LD schema for Google Rich Results.

Frequently Asked Questions

1. What is clean agent fire extinguisher refilling?

Answer: Clean agent fire extinguisher refilling involves replacing or recharging the extinguishing gas (such as FM-200, Novec™ 1230, CO₂, or Inergen) inside suppression system cylinders after use or periodic testing. It ensures proper pressure, purity, and readiness for immediate activation in case of fire.

2. How often should clean agent fire suppression cylinders be refilled or tested?

Answer: As per NFPA 2001 and ISO 14520, clean agent cylinders should be visually inspected every 6 months and pressure-tested or refilled every 5 years or after any discharge event. Regular refilling guarantees compliance and operational reliability.

3. What types of fire suppression systems do you refill?

Answer: We provide refilling services for all major clean agent and gas-based fire suppression systems, including FM-200 (HFC-227ea), Novec™ 1230 (FK-5-1-12), CO₂ systems, Inergen (IG-541), Argonite (IG-55), and tube-based modular systems for control panels and CNC machines.

4. Can refilling be done on-site, or do the cylinders need to be transported?

Answer: Depending on system type and capacity, we offer both on-site refilling (for modular/tube-based systems) and factory refilling (for large CO₂ or total flooding systems). All work is performed by certified technicians with calibrated equipment.

5. How do I know if my suppression system needs refilling?

Answer: Indicators include low-pressure gauge readings, leakage reports, discharged indicators, or maintenance alerts. A professional inspection can confirm whether the cylinder requires refilling or hydro-testing.

6. Is the refilling process safe for the environment?

Answer: Yes. We follow eco-friendly handling procedures and ensure that agents like Novec™ 1230 and FM-200 are recovered and refilled using closed systems, minimizing any atmospheric release and ensuring sustainability.

7. Do you provide refilling for imported suppression systems or specific brands?

Answer: Yes. We refill and test cylinders from all major global brands including Kidde, Tyco, Minimax, Ceasefire, Siemens, Honeywell, and Securiton, ensuring compatibility and OEM-grade performance.

8. Do you issue a refilling and test certificate after the service?

Answer: Absolutely. Every refilled cylinder is accompanied by a Refilling and Hydro-Test Certificate, detailing pressure, weight, and inspection records to ensure NFPA and BIS compliance.

9. What is the turnaround time for clean agent refilling?

Answer: Most refilling jobs are completed within 24–48 hours. Large-scale or multi-cylinder refilling projects may take slightly longer depending on volume and agent type.

10. Do you offer AMC (Annual Maintenance Contracts)?

Answer: Yes. Fire Engineering Technology offers annual and bi-annual maintenance contracts for all types of fire suppression systems, including regular inspection, refilling, and functional testing.

Fire Extinguishers Refilling Service

AFFF WCO2 Fire Extinguishers Refilling Service

FE 36 Fire Extinguishers Refilling Service

CO2 Type Fire Extinguishers Refilling Service.

HFC227 Fire Extinguishers Refilling Service

DCP Extinguisher Refilling Service