Electrical Panel Fire Suppression System by Fire Engineering Technology is a high-demand, most-searched and Google-optimized fire protection solution designed for electrical panels, control panels, MCC panels, LT/HT panels, PLC cabinets and server racks. This system is widely searched as:

Electrical Panel Fire Suppression System

Automatic Fire Suppression for Electrical Panels

Electrical Panel Fire Protection System

Tube Based Fire Suppression System

Clean Agent Fire Suppression System for Panels

Fire Protection System for Control Panels

Industrial Electrical Fire Safety System

Fire Engineering Technology promotes this system as a premium and trusted brand in India for advanced electrical panel fire safety. Our solution ensures instant detection, fast suppression and complete safety of critical electrical infrastructure, helping your business rank higher in safety compliance and Google search visibility.

This system is ideal for factories, industries, data centers, commercial buildings, power plants, substations and automation industries looking for the best electrical panel fire suppression system manufacturer and supplier in India.

Electrical panels are highly vulnerable to fire due to:

Short circuits

Overheating components

Loose wiring connections

Insulation failure

Power fluctuations

A small spark can lead to complete shutdown, equipment damage and safety risk. Our automatic electrical panel fire suppression system provides localized protection and eliminates fire before it spreads.

The Electrical Panel Fire Suppression System works on a very simple and automatic principle:

A heat-sensitive detection tube is fixed inside the electrical panel.

When fire or high heat occurs, the tube senses the temperature rise.

At critical temperature (90°C – 120°C), the tube bursts at the exact fire point.

The extinguishing gas is released directly onto the fire.

Fire is suppressed instantly before it spreads.

This direct action system ensures:

Quick fire control within seconds

No water damage

No residue

Complete protection of electrical components

It is one of the most searched and trusted solutions for automatic fire suppression for electrical panels, making Fire Engineering Technology a preferred brand visible in top Google search results.

Available options include CO₂, FM-200, Novec 1230 and tube-based clean agent systems for maximum efficiency and performance.

Automatic fire detection and suppression

Fast response within seconds

Compact and space-saving design

Non-conductive & residue-free extinguishing agent

Low maintenance

No power supply required (optional control panel integration)

Environmentally friendly & safe

UL, NFPA and ISO compliant

Electrical Control Panels

Switchgear Panels

Distribution Boards

PLC Panels

UPS Systems

Server Cabinets

Industrial Automation Units

Battery Rooms

Renewable Energy Panels

Prevents major fire accidents

Reduces equipment damage cost

Minimizes operational downtime

Increases system life

Ensures business continuity

Enhances workplace safety compliance

Our Electrical Fire Suppression System is engineered as per Indian and international fire safety standards including NBC, NFPA and ISO guidelines.

Tube Based Fire Suppression System

Clean Agent Fire Suppression System

CO₂ Gas Based Fire Protection System

Novec 1230 Fire Suppression System

FM-200 Fire Suppression System

Direct & Indirect Low Pressure Systems

Certified Manufacturer & Supplier

Customized Solutions

Quick Installation

Expert Technical Support

Strong After-Sales Service

Proven Performance Across Industries

Fire Engineering Technology is a trusted name in electrical panel fire protection system manufacturing, offering high-performance products with guaranteed reliability and efficiency.

Our product page is optimized using high-ranking keywords such as:

Electrical Panel Fire Suppression System

Automatic Fire Suppression System

Electrical Panel Fire Protection

Clean Agent Fire Protection System

Tube Based Fire Suppression System

Fire Safety System for Electrical Panels

Industrial Fire Suppression System

Gas Based Fire Protection System

Fire Engineering Technology Manufacturer

Easy installation without disruption to operations. Our systems come with flexible mounting options and require minimal maintenance, making them perfect for long-term protection.

Send Enquiry

By Fire Engineering Technology

The Clean Agent Based Fire Suppression System by Fire Engineering Technology is a highly reliable automatic fire extinguishing system designed to protect critical assets, sensitive equipment, and enclosed hazards without causing damage, residue, or downtime. This advanced system suppresses fire rapidly at its initial stage while being safe for people, equipment, and the environment.

Clean agent systems are widely used where water, foam, or powder-based fire suppression is not suitable, such as electrical rooms, server rooms, CNC machines, control panels, and data centers.

A clean agent fire suppression system uses a non-conductive, electrically safe, and residue-free gaseous extinguishing agent to suppress fire by absorbing heat and interrupting the combustion process. After discharge, the protected area remains clean with no need for cleanup or equipment replacement.

Common clean agents include FK-5-1-12 (Novec 1230 alternative) and HFC-based agents, making the system ideal for Class A, Class B, and Class C fire risks.

Automatic Fire Detection & Suppression

No Residue, No Water Damage

Safe for Electrical & Electronic Equipment

Non-Conductive & Environment Friendly

Fast Acting – Fire Suppressed in Seconds

Compact Cylinder Design

Low Maintenance & Long Service Life

Suitable for Occupied Areas

Electrical Panels & Control Panels

CNC Machines & Machine Enclosures

Server Rooms & Data Centers

UPS Rooms & Battery Rooms

Telecom Equipment Rooms

Laboratories & R&D Facilities

Medical & Diagnostic Equipment Rooms

Museums, Archives & Record Rooms

Automatic Clean Agent Gas Flooding System

Clean Agent Tube Based Fire Suppression System

Total Flooding Fire Suppression System

Local Application Clean Agent System

Standalone Clean Agent Fire Extinguishing Units

Fire Detection – Heat or flame triggers the detection tube or sensor

Automatic Activation – Cylinder valve opens instantly

Agent Discharge – Clean agent floods or targets the fire source

Fire Suppression – Fire is extinguished within seconds

Trusted manufacturer & system integrator

Custom-designed clean agent solutions

High-quality cylinders, valves & tubing

Compliance with international fire safety standards

PAN-India supply, installation & service support

clean agent based fire suppression system, clean agent fire extinguishing system, automatic clean agent fire protection system, gas flooding fire suppression system, FK-5-1-12 clean agent system, Novec 1230 fire suppression system, electrical panel fire suppression, CNC machine clean agent fire system, server room fire suppression system, residue free fire suppression system.

Protect your valuable assets with smart, clean, and automatic fire protection.

Choose the Clean Agent Based Fire Suppression System by Fire Engineering Technology for advanced, damage-free, and reliable industrial fire safety solutions.

Fire Engineering Technology's "FET FIREFINDER" is an effective solution for the protection of high value equipment. FET FIREFINDER uses HFC227ea or FK-5-1-12 as extinguishing agents and include a thermal heat and flame sensitive tubing as detection device. The system is activated automatically by the detection device and does not require any power supply; some configuration allow a back-up manual activation.

FET FIREFINDER can be configured with a direct or indirect installation. Direct FET FIREFINDER use the sensitive tube both as detection device and suppression delivery. On the other hand Indirect FET FIREFINDER use the sensitive tube as detection device and system activation; the suppression delivery is achieved with a separate pipeline distribution ended with discharge nozzles. FET FIREFINDER agents are tipically superpressurized with nitrogen at 15 bar.

FET FIREFINDER is manufactured under a certified ISO 9001 Quality Management System in order to ensure production stability and components compliance to intended performance characteristics.

Send Enquiry

The extinguishing agent 3M Manufactured Novec TM 1230 acts both physically and chemically. Novec1230 is widely used all over the world and, thanks to its environmental properties, has become in many countries the extinguishing agent par excellence for IT and electrical applications risk management.

Novec 1230 gas is indicated for class A and class B fires and it is designed as a total saturation extinguishant. It is neither corrosive nor electrically conductive and thus it does not cause any damage for short circuits or residues on sensitive components.

Novec 1230 is colorless, almost odorless and it is in liquid state at ambient temperature. Its molecule consists of carbon, fluorine and oxygen. Novec 1230 extinguishes the flame thanks to combustion interruption.

So it is widely used for

- Electrical Panel Fire Suppression System.

- Electrical Room fire suppression system.

- Office area fire suppression system.

- Server Rack fire suppression system,

- Server Room fire suppression system,

- Flameable liquids fire suppression system.

Novec 1230 fluid is designed to prevent any concern for environmental effects; thanks to peculiar properties Novec 1230 re-defined the idea of "sustainability" in clean agent fire protection:

By Fire Engineering Technology – Advanced Automatic Fire Protection for Commercial Kitchens

Fire Engineering Technology is a leading manufacturer and supplier of Kitchen Fire Suppression Systems in India, offering fully automatic, reliable, and eco-friendly protection for commercial kitchens, hotels, restaurants, canteens, and food processing units.

Our system uses Wet Chemical (Potassium Acetate-based) clean agent technology that quickly suppresses flames and prevents re-ignition of cooking oils and grease fires, ensuring total safety and minimal damage.

Designed in compliance with NFPA 17A and UL 300 standards, our Automatic Kitchen Fire Suppression System is engineered to activate instantly in case of fire, even when the kitchen is unattended.

When a fire starts in a cooking appliance, fryer, or hood, the heat detection line or fusible link senses a temperature rise and automatically triggers the wet chemical discharge.

The agent rapidly cools and blankets the oil surface, creating a foam layer that:

Suppresses flames instantly

Prevents oxygen supply

Stops re-ignition

The system simultaneously shuts off the fuel or power supply to ensure complete fire control and operator safety.

Wet Chemical Storage Cylinder (Potassium Acetate / Potassium Carbonate)

Detection Network (fusible link or heat sensing tube)

Nozzles and Piping Network for hoods, ducts, and appliances

Manual Pull Station for emergency activation

Automatic Gas or Power Shutoff Valve

Control Panel (Optional) for system supervision

By Fire Engineering Technology – Complete Fire Safety Solutions for Commercial & Industrial Kitchens

Fire Engineering Technology is India’s leading manufacturer and supplier of all types of Kitchen Fire Suppression Systems, engineered to protect commercial, industrial, and institutional kitchens from cooking oil and grease fires (Class F fires).

Our automatic fire suppression systems are designed to detect, control, and extinguish fires quickly — even when no one is present — providing round-the-clock safety in restaurants, hotels, food courts, canteens, and industrial kitchens.

We manufacture Tube-Based, Wet Chemical, Total Hood, and Pre-Engineered Automatic Fire Suppression Systems that meet NFPA 17A, UL 300, and Indian NBC standards.

A compact, automatic, and self-activating system ideal for small to medium-sized kitchens and individual cooking appliances.

How It Works:

A heat-sensitive detection tube runs across the risk area. When it senses fire (typically 110°C–150°C), the tube bursts and releases the wet chemical agent directly on the fire, extinguishing it instantly.

Features & Benefits:

✅ No power source required

✅ Instant localized activation

✅ Compact and easy to install

✅ Safe for electrical and oil fires

✅ Maintenance-free and cost-effective

Applications:

Control panels of kitchen equipment, fryers, small hoods, and food trucks.

The most common and reliable system for commercial kitchens and industrial cooking setups.

It uses potassium-based wet chemical agents (Potassium Acetate / Carbonate) to quickly cool and seal hot oils and fats, preventing re-ignition.

Features & Benefits:

✅ Ideal for fryers, ovens, grills & hoods

✅ UL 300 & NFPA 17A certified

✅ Forms a foam layer to smother flames

✅ Safe for food and stainless steel surfaces

✅ Automatic gas or power shutoff on activation

Applications:

Restaurants, hotels, hospitals, institutional canteens, food courts, and central kitchens.

A complete pre-engineered fire suppression solution for large commercial kitchens that provides full coverage for cooking ranges, hoods, and exhaust ducts.

How It Works:

The system detects high heat in the hood or duct through fusible links or sensors, activates automatically, and discharges wet chemical agent through nozzles positioned over cooking equipment and duct openings.

Features:

✅ Protects multiple appliances simultaneously

✅ Covers ducts, filters & hoods

✅ Automatic shutdown of fuel/gas supply

✅ Certified to NFPA 17A & UL 300 standards

✅ Refill & recharging available locally

A factory-assembled, plug-and-play system for modular kitchen setups, QSR chains, and industrial canteens.

Advantages:

✅ Quick installation & minimal maintenance

✅ Compatible with any kitchen layout

✅ Easy recharge and service

✅ Tested for high efficiency and durability

Integrated with all Fire Engineering Technology kitchen systems, this feature ensures immediate gas or electrical cutoff when the system is activated, preventing further fuel supply and ensuring complete extinguishment.

Automatic detection & activation

Suitable for Class F (cooking oil & fat) fires

Environmentally safe and non-toxic agents

Complies with NFPA 17A / UL 300 standards

Manual pull station for emergency use

Compact design with easy refill option

Integrated gas & power shutoff system

CE, UL, and BIS certified components

Our All Types of Kitchen Fire Suppression Systems are ideal for:

🍴 Restaurants & Hotels

🏭 Food Processing Plants

🏫 Institutional Kitchens & Mess Halls

🏢 Corporate Cafeterias & Food Courts

🛳️ Marine & Offshore Galleys

🍔 QSR & Franchise Kitchens

🚚 Food Trucks and Mobile Kitchens

| Parameter | Specification |

|---|---|

| Agent Type | Wet Chemical (Potassium Acetate / Carbonate) |

| System Type | Tube-Based / Wet Chemical / Total Hood / Pre-Engineered |

| Activation | Automatic (Heat/Fusible Link) / Manual |

| Fire Class | Class F (Cooking Oil / Fat Fires) |

| Standards | NFPA 17A / UL 300 / ISI / CE |

| Application | Hood, Ducts, Ovens, Fryers, Cooking Ranges |

| Gas Shutoff | Automatic / Manual |

| Discharge Time | ≤ 10 seconds |

Fire Engineering Technology is one of India’s most trusted names in kitchen and industrial fire suppression manufacturing.

With decades of fire safety experience, we deliver customized solutions designed for your specific kitchen layout and risk profile.

We provide:

✅ Design, Installation & Commissioning

✅ AMC & Refilling Support Across India

✅ UL / NFPA Certified Systems

✅ Nationwide Service Network

Our systems are installed in leading hotel chains, restaurants, and industrial kitchens across India — trusted for their performance, reliability, and global safety compliance.

Send Enquiry

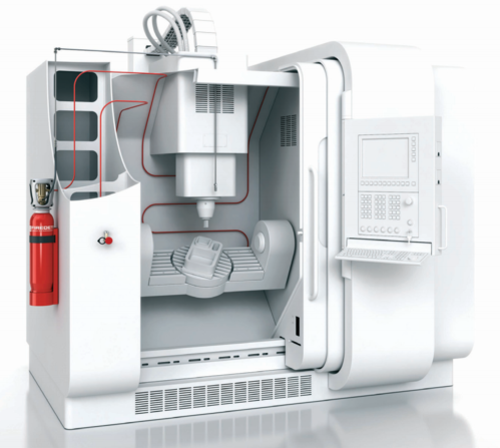

Fire Engineering Technology is a leading Indian manufacturer of CNC machine fire suppression systems, providing fully automatic fire detection and suppression solutions for CNC machines, EDMs, VMCs, HMCs, and other metal machining centers.

Our advanced Tube-Based Fire Suppression System ensures instant detection and extinguishing of fire directly inside the CNC machine enclosure — protecting high-value assets, minimizing downtime, and ensuring operator safety.

CNC machines are critical to precision manufacturing, but they are also high-risk fire zones due to:

Hydraulic & coolant oil leakage

Metal dust or fine shavings ignition

Overheating of spindle motors

Short-circuit or electrical panel failure

Flammable cutting fluids & lubricants

These factors can lead to rapid flash fires, causing machine damage, production loss, and safety hazards.

An automatic CNC fire suppression system ensures immediate detection and suppression before the fire spreads — without manual intervention.

The system uses heat-sensitive polymer detection tube technology that provides 24/7 automatic monitoring inside the CNC enclosure.

When the temperature exceeds 110°C–150°C, the polymer tube bursts at the hottest point, releasing the fire suppression agent (Clean Agent / CO₂ / Novec 1230) directly on the fire source.

This instant discharge:

Stops fire at its origin

Prevents spread to adjacent components

Protects electronics, servo drives, hydraulic parts, and control panels

The detection tube itself acts as the delivery line.

When burst, it releases the extinguishing agent directly on the fire.

👉 Perfect for single CNC machines or compact enclosures.

The tube senses fire and triggers a valve and nozzle network.

The extinguishing agent is discharged through multiple nozzles for total flooding.

👉 Ideal for large CNC machines or multi-chamber setups.

Clean Agent (FM-200 / HFC-227ea) – Non-corrosive, residue-free, and safe for electronics and optics.

Novec™ 1230 – Environmentally friendly clean agent; quick suppression, zero residue, and safe for occupied areas.

CO₂ Fire Suppression – Ideal for unmanned or enclosed CNC machine spaces; effective for metal fires and hydraulic fires.

Dry Chemical Powder (ABC / D) – For high-risk industrial operations where flammable oils are present.

All systems comply with NFPA 2001, ISO 14520, UL, and CE standards.

Our CNC machine fire suppression systems are ideal for:

CNC Turning Centers & Lathes

VMC / HMC Machining Centers

EDM (Electrical Discharge Machines)

Hydraulic Presses & Robotic Machines

Laser & Plasma Cutting Machines

Die Casting & Molding Machines

Precision Milling & Drilling Systems

Automated Tooling & PLC Panels

✅ Automatic detection & suppression – no manual input required

✅ Zero electrical damage – safe for electronics & precision tools

✅ Fast activation (<10 seconds)

✅ Power-free operation

✅ Compact, modular, and maintenance-friendly

✅ UL / CE certified components

✅ Environmentally friendly clean agents

✅ Custom-engineered for all CNC models & enclosures

✅ Pre-engineered system as per NFPA 2001 & ISO 14520 standards

As a trusted Indian manufacturer and exporter of CNC fire suppression systems, we specialize in tube-based, pre-engineered, and clean agent systems designed for industrial automation and CNC fire safety.

We offer:

🔹 Design, engineering, and installation

🔹 Refilling & AMC services

🔹 Nationwide and export support

🔹 Custom configurations for all major CNC brands (Fanuc, Mazak, Haas, DMG, etc.)

Our suppression systems are approved and preferred by industries in automotive, aerospace, tooling, defense, and electronics manufacturing sectors.

Send Enquiry

Fire Engineering Technology is a leading Indian manufacturer and supplier of Novec 1230 (FK-5-1-12) Fire Suppression Systems, engineered to protect critical environments where water, foam, or powder-based systems could cause damage or downtime.

Our Novec 1230 clean agent systems are environmentally friendly, non-conductive, and residue-free, ensuring total fire protection for data centers, server rooms, electrical control panels, laboratories, healthcare facilities, and industrial automation equipment.

Novec™ 1230, also known as FK-5-1-12, is a next-generation clean agent fire suppression fluid developed to replace HFC-based gases like FM-200.

It extinguishes fire by absorbing heat energy from the flame zone—without depleting oxygen or leaving residue.

The chemical name is Dodecafluoro-2-methylpentan-3-one, and it provides rapid, clean, and people-safe fire protection.

✅ Zero ozone depletion potential (ODP)

✅ Global Warming Potential (GWP) < 1

✅ Atmospheric lifetime < 5 days

✅ Safe for occupied areas

This makes it one of the most sustainable fire suppression agents available today.

When a fire is detected, the Novec 1230 agent is released and rapidly vaporizes, absorbing heat and breaking the combustion chain reaction.

It suppresses fire in seconds, leaving no residue and ensuring equipment remains operational after discharge.

Because it is non-conductive, it is ideal for use around sensitive electrical and electronic equipment.

Designed to protect an entire room or enclosure, the Novec 1230 (FK-5-1-12) agent is stored in high-pressure cylinders connected through a piping and nozzle network.

Upon activation (via detection system or manual release), the gas is discharged to flood the entire space.

Applications:

Data centers

Server rooms

Electrical control rooms

Communication centers

Transformer rooms

Healthcare & clean rooms

Features:

Fast discharge (under 10 seconds)

Even distribution of gas

Safe for people & equipment

Designed per NFPA 2001 / ISO 14520

Compact and self-contained system where each cylinder directly protects a specific enclosure or equipment.

Often used in control panels, machinery enclosures, and small electrical cabinets.

Applications:

CNC machines

PLC & electrical control panels

Battery energy storage systems (BESS)

ATM machines & kiosks

Medical equipment cabinets

Features:

Space-saving modular units

No piping required

Quick installation & low maintenance

Localized protection at fire origin

This system uses a flexible polymer detection tube that senses heat and releases the clean agent automatically.

When the tube bursts due to heat, Novec 1230 (FK-5-1-12) is discharged directly at the fire source or through a nozzle network (direct/indirect type).

Applications:

Electrical control cabinets

Server racks & UPS panels

CNC machines

Solar inverters

EV charging cabinets

Features:

Automatic detection & suppression

No external power required

Fastest localized response

Ideal for compact or enclosed spaces

✅ Environmentally safe (GWP < 1, ODP = 0)

✅ Safe for people & electronics

✅ No residue, no cleanup

✅ Compact storage (smaller cylinders)

✅ Non-corrosive & electrically non-conductive

✅ Complies with NFPA 2001 & ISO 14520

✅ Quick refilling & easy maintenance

✅ Ideal replacement for FM-200 / Halon systems

Data Centers & Server Rooms

Telecommunication Centers

Hospitals & Operation Theaters

Power & Energy Sector (Switchgear / Transformer Rooms)

Manufacturing Automation Lines

Pharmaceutical Clean Rooms

Control Panels & Instrument Cabinets

CNC Machines & Laser Equipment

Battery Energy Storage Systems (BESS)

Marine & Offshore Equipment

All Fire Engineering Technology Novec™ 1230 systems are designed and tested as per:

NFPA 2001 – Clean Agent Fire Extinguishing Systems

ISO 14520 – Gaseous Extinguishing Systems

UL Listed & CE Certified Components

Environmentally compliant with F-Gas regulations

India’s trusted manufacturer & exporter of clean agent fire suppression systems

Customized design, installation & commissioning

Refilling & AMC services across India

Compliance with NFPA, UL, and BIS standards

Engineered solutions for all industries

We provide turnkey solutions from design to maintenance, ensuring your assets are protected 24 × 7 with a future-ready, eco-safe clean agent system.

This FAQ is designed for placement on the product/service webpage for Novec™ 1230 / FK-5-1-12 Fire Suppression Systems by Fire Engineering Technology. Use the JSON-LD below to enable Google FAQ rich results.

Answer: Novec™ 1230 (chemical name: dodecafluoro-2-methylpentan-3-one) is a clean, non-conductive fire suppression agent that extinguishes fires primarily by absorbing heat from the flame zone. It vaporizes on discharge, suppresses fire rapidly, and leaves no residue—making it safe for sensitive electronics and critical equipment.

Answer: Yes. Novec™ 1230 has zero ozone depletion potential (ODP = 0) and a global warming potential (GWP) of less than 1. It has a short atmospheric lifetime and is approved for use in occupied spaces when systems are designed and installed according to NFPA 2001 and local codes.

Answer: We supply three main system types: (1) Total Flooding Systems for room protection, (2) Modular / Pre-Engineered Systems for localized equipment protection, and (3) Tube-Based Systems that combine detection and discharge for enclosed cabinets and machinery.

Answer: Typical applications include data centers, server rooms, telecom shelters, electrical switchgear and control rooms, CNC and machining enclosures, battery energy storage systems (BESS), hospitals, laboratories, and clean rooms.

Answer: Novec™ 1230 systems are designed for rapid discharge—typically achieving effective fire suppression within seconds of actuation when installed as per manufacturer guidelines and NFPA 2001 design concentrations.

Answer: No. Novec™ 1230 is residue-free and non-corrosive. After discharge, there is no neutralization or cleanup required for protected equipment, significantly reducing downtime.

Answer: In most cases, yes. Novec™ 1230 is a modern replacement for older HFC or Halon systems due to its superior environmental profile (GWP < 1) and similar extinguishing performance. A site-specific engineering evaluation is required to confirm compatibility and required concentrations.

Answer: Novec™ 1230 systems should be designed, installed, and commissioned in accordance with NFPA 2001 (Clean Agent Fire Extinguishing Systems) and ISO 14520. Components such as valves, cylinders, and detection equipment typically carry UL, CE, or equivalent approvals.

Answer: Routine inspection and preventative maintenance are recommended annually for most systems; critical sites may require more frequent checks. Fire Engineering Technology offers AMC and refilling services to ensure compliance and readiness.

Answer: System selection depends on protected volume, asset sensitivity, occupancy, and local regulations. Fire Engineering Technology provides a free site survey and engineering proposal to recommend the optimal solution—be it total flooding, modular, or tube-based systems.

Send Enquiry

Fire in Electrical Panels is a serious hazard to life and property. Occurrence of fire besides leading to personnel injuries and property damage also leads to loss of productivity and precious time.

The primary cause of fire may be due to short circuit /overheating of certain components in the panel board. Since most of the Panel areas are unmanned and completely closed, fire inside the panel is not visible and accessible from out side till it becomes too big, dangerous and unmanageable.

The Fire Protection System envisaged for electrical panels calls for early detection of fire and quenching the same by flooding the electrical panel with CO2 besides giving out an audio visual alarm.

SYSTEM OPERATION

The main features of the system are:

The detection of fire is primarily made by a FIRE FINDER Tube.

FIRE FINDER Tube can Detect Fire anywhere along its length. The FIRE FINDER Tube is highly flexible and can be conveniently routed to cover the various hazard areas. The FIRE FINDER Tube is a fixed temperature sensing Tube made up of a high Tech Polymer material to cater to long term leak resistance, flexibility, and accurate and consistent heat sensitivity. One end of the FIRE FINDER Tube is connected to the differential High Pressure fitted on the CO2 Cylinder and the other end to an End of Line Adapter through a Non return valve. The Co2 Cylinder Assy is placed over Weight Monitoring System/ Clamped on wall/ clamped over Panel.

A Pressure Switch is connected to the End of Line Adapter which is electrically connected to an Audio-Visual Alarm Unit/ Master Control Unit.

In the event of a Fire contacting the FIRE FINDER Tube, the Tube starts melting and bursts at the hottest point. This leads to a rapid reduction of pressure in side the Tubing. The reduction of Pressure will make the Differential High Pressure Valve fitted on the Co2 Cylinder open out instantaneously. The Co2 Stored in the Cylinder will get released through the tube at the burst point into the panel. The drop of pressure in the FIRE FINDER Tube followed by reduction in the weight of the Co2 in the cylinder due to the discharge will activate an Audio-Visual Alarm.

SYSTEM CONFIGURATION

FIRE FINDER TUBE

The FIRE FINDER Tube is a flexible detection and delivery device installed within the protected equipment. The FIRE FINDER Tube does not rely on detecting fire at a single point but at anywhere along its length.

CARBON DI-OXIDE CYLINDER ASSEMBLY

A self-activating differential High Pressure Valve is fitted to the Co2 Cylinder through which the FIRE FINDER Tube is connected. The Valve contains a pressure regulator, which reduces Co2 pressure in the FIRE FINDER Tube to 15 bars.

In the event of a Fire, the FIRE FINDER Tube bursts open at the hottest spot letting out the pressure in the FIRE FINDER tube. The differential pressure arising of this activates the plunger inside the differential High-pressure valve and the Co2 Gas gets released from the out let port through the burst point.

MANUAL RELEASE VALVE

The Manual release Valve is intended for activation of the Co2 system manually. It consists of a Ball Valve actuator mechanism. To operate the Valve, pull out the locking pin and turn the knob to “ON” position. This will activate the system instantaneously.

NOTE : - Leave Knob in “ON” position till Co2 from the Cylinder is discharged completely.

Caution: Operation of the manual release valve will discharge the Co2 from the cylinders instantaneously. Also breakage of the seal voids warranty.

PRESSURE SWITCH

The Pressure Switch monitors the pressure inside the FIRE FINDER Tube. It is connected to the FIRE FINDER Tube through an End of Line Adapter. The Pressure Switch operates at a pre-set pressure of 5 to 8 bar. In the event of a reduction in pressure, the Pressure Switch opens and activates the Audio-Visual Alarm.

CONTROL UNIT

The Control Unit is located inside the Control room and controls the operation of the system. It is connected to the Mains 230V A.C. It contains inbuilt power conditioning circuits to enable isolation and operation of the system at an input volt of 24V to 30 V DC.

The Control Unit continuously monitors the status of Smoke Detector and FIRE FINDER Tube. In the event of a fire sensed by Smoke Detector or FIRE FINDER Tube the control unit will

(1) Activate Audio Alarm

(2) Activate the Solenoid Valves.

In the event of a Fire condition. Which leads to a rapid reduction of pressure in side the Tubing. The reduction of Pressure will make the Differential High Pressure Valve fitted on the Co2 Cylinder open out instantaneously. The Co2 Stored in the Cylinder will get released through the pre-defined Nozzle points. The drop of pressure in the FIRE FINDER Tube due to the discharge will activate an Audio-Visual Alarm. The control unit will indicate fire condition by lighting up RED Lamp.

AUDIO - VISUAL ALARM

Audio-Visual Alarm is located near the Control Room to alert people around on the activation of Co2 flooding System. It monitors the pressure in the FIRE FINDER Tube through the Pressure Switches.

SYSTEM FEATURES

The following are the features of the FIRE FINDER Automatic Fire Protection System.

Send Enquiry

By Fire Engineering Technology – Advanced Foam-Based Fire Suppression for Industrial Applications

Fire Engineering Technology is a leading manufacturer and supplier of Foam Flooding Fire Suppression Systems in India, providing custom-engineered foam-based protection for paint booths, automotive plants, chemical industries, and flammable liquid storage areas.

Our AFFF (Aqueous Film Forming Foam) and AR-AFFF (Alcohol Resistant Foam) systems are specifically designed for Class B fires caused by flammable liquids such as paints, solvents, thinners, and fuels.

The Foam Flooding System instantly forms a foam blanket over the burning surface, cutting off oxygen, cooling the area, and preventing re-ignition, ensuring total fire control in paint spray booths, dip tanks, and mixing rooms.

When a fire is detected by flame, heat, or smoke sensors, the control panel automatically activates the foam proportioning and discharge system.

Foam solution (AFFF or AR-AFFF) is mixed with water in a specific ratio and distributed through a network of foam generators or sprinklers, blanketing the entire area.

Foam cools the fuel surface, lowering the temperature below ignition.

A foam blanket seals vapors, preventing oxygen contact.

The agent prevents re-ignition, ensuring long-term suppression stability.

This method is highly effective for liquid fires in confined and ventilated areas, such as automotive paint booths or industrial finishing lines.

Used where full area coverage is required — typically for large paint booths or dip tanks.

Employs foam chambers, generators, or sprinklers.

Ideal for automotive paint lines, varnish plants, and solvent storage areas.

Controlled automatically through fire detection panels and foam proportioning systems.

A deluge valve-based system that releases a high volume of foam-water solution instantly upon fire detection.

Suitable for flammable liquid handling areas.

Activated by detectors or manual release stations.

Provides fast suppression and rapid cooling.

A specialized foam system designed for paint application booths, drying chambers, and exhaust ducts.

Uses AFFF foam spray nozzles or high-expansion foam generators.

Automatically shuts down air circulation fans and fuel supply.

Reduces contamination and fire damage to paint lines.

Protects specific areas like paint mixing tanks, solvent containers, or fuel filling stations using foam monitors or handline nozzles.

Simple design and quick operation.

Ideal for spot protection or equipment-level safety.

Our Foam Fire Suppression Systems are widely used in:

🚗 Automotive Paint Booths & Spray Lines

🏭 Chemical & Solvent Storage Areas

🎨 Paint Mixing Rooms & Drying Chambers

🛢️ Fuel Filling and Oil Storage Areas

⚙️ Industrial Manufacturing & Finishing Units

🏗️ Refineries & Process Plants

✅ Suitable for Class B flammable liquid fires

✅ Fast-acting total flooding or deluge configuration

✅ Works with AFFF, AR-AFFF, or Fluorine-Free Foam (FFF)

✅ Automatic detection & activation via control panel

✅ Manual override for emergency release

✅ NFPA 11, NFPA 16, and BIS compliant design

✅ Low maintenance and long service life

| Parameter | Specification |

|---|---|

| Agent | AFFF / AR-AFFF / FFF Foam Concentrate |

| Fire Class | Class B (Flammable Liquids, Solvents, Paints) |

| Discharge Type | Flooding / Deluge / Local Application |

| Activation | Automatic (Detector Signal) / Manual Release |

| Working Pressure | 7 – 10 bar |

| Foam Expansion Ratio | 8:1 to 100:1 (depending on agent) |

| Standards | NFPA 11 / NFPA 16 / BIS / CE Certified |

| Application Area | Paint Booths, Dip Tanks, Solvent Rooms |

Fire Engineering Technology provides end-to-end foam fire suppression solutions, including design, manufacturing, installation, and annual maintenance.

Our systems are designed for maximum reliability and compliance, with approvals from NFPA, CE, and BIS standards.

We specialize in custom-engineered paint booth fire suppression systems using AFFF, AR-AFFF, or Fluorine-Free Foam agents to deliver rapid and residue-free fire protection.

With a strong nationwide service network, we ensure timely commissioning, testing, and refilling support for all foam flooding installations.

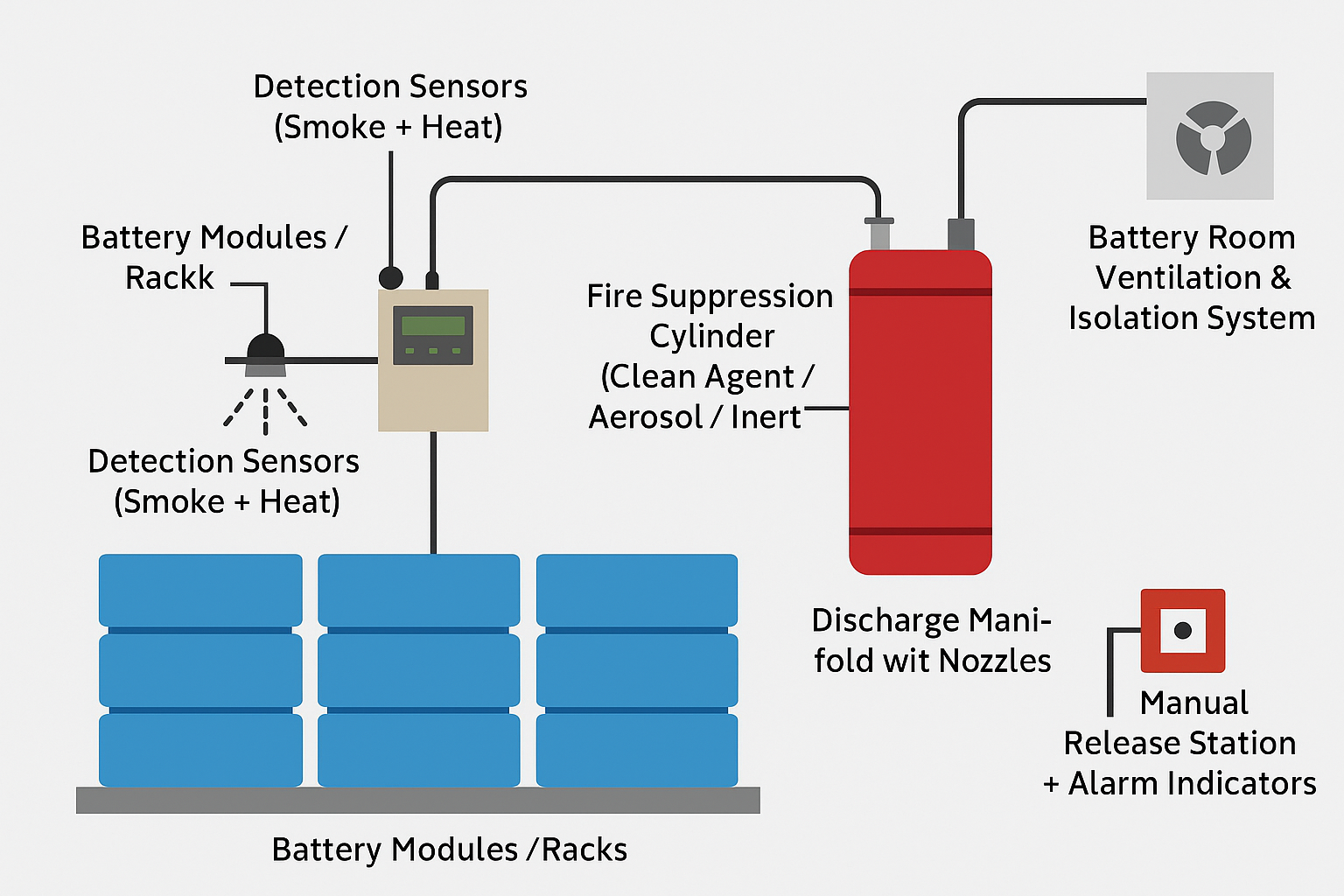

Fire Engineering Technology is a leading Indian manufacturer and supplier of BESS (Battery Energy Storage System) fire suppression systems, providing advanced, automatic, and clean agent-based fire protection solutions for lithium-ion battery storage facilities.

With the rapid growth of renewable energy, Battery Energy Storage Systems (BESS) have become critical assets in power grids and solar/wind energy projects. However, these systems are prone to thermal runaway, short circuits, and cell combustion — creating a high risk of fire and explosion.

Our BESS fire suppression systems are engineered to detect, contain, and suppress such fires in the earliest stages using clean agent gases, aerosols, or water mist systems that are eco-friendly, residue-free, and NFPA 855 compliant.

The system is built using:

Detection: Heat or smoke sensors and linear heat detection cables installed inside each battery rack or container.

Suppression: Clean agent (Novec 1230 / FM-200), Aerosol, or Inert Gas (IG-541 / IG-100) released through discharge nozzles or tube-based systems.

Activation: Fully automatic upon temperature rise or smoke detection, with manual override options.

Control Panel: Integrated with fire alarm and shutdown interface for safe isolation.

BESS Fire Suppression System Layout Includes:

Battery Modules / Racks

Detection Sensors (Smoke + Heat)

Detection Panel (Control & Monitoring Unit)

Fire Suppression Cylinder (Clean Agent / Aerosol / Inert Gas)

Discharge Manifold with Nozzles

Battery Room Ventilation & Isolation System

Manual Release Station + Alarm Indicators

🟢 Operation Flow:

Detection → Control Signal → Suppression Discharge → Power Isolation → Post-ventilation.

Battery Energy Storage Systems (Containerized / Modular)

Renewable Energy (Solar + Wind + Microgrids)

Electric Vehicle Charging Stations

Power Substations & Backup Battery Rooms

Data Centers with Battery Backup Systems

✅ Fast detection of lithium-ion thermal runaway

✅ Clean agent or aerosol discharge within seconds

✅ Non-conductive and safe for electrical systems

✅ Environmentally friendly (Zero ODP, Low GWP)

✅ NFPA 855, 70E, and IEC 62619 compliant design

✅ 24x7 automatic protection, no human intervention needed

A BESS Fire Suppression System is a specialized automatic fire protection solution for Battery Energy Storage Systems, using clean agent gases, inert gases, or aerosol suppression to prevent and control lithium-ion battery fires.

Lithium-ion batteries can ignite due to thermal runaway, caused by overcharging, overheating, or internal short circuits. This leads to rapid temperature rise and combustion of electrolyte gases — requiring fast, automatic suppression.

The system detects early heat or smoke inside battery cabinets using linear heat cables or sensors. Once triggered, it automatically releases a clean agent or aerosol through nozzles to extinguish fire and prevent re-ignition.

Fire Engineering Technology offers:

Novec 1230 / FM-200 Clean Agent Systems

Aerosol Fire Suppression Systems

Inert Gas Systems (IG-541, IG-100)

Each is designed based on enclosure size and battery chemistry.

Rapid suppression with zero residue

Safe for electrical components

Eco-friendly and non-corrosive agents

Automatic and power-independent activation

Compliance with NFPA 855, NFPA 2001, and UL 9540A

Yes. Systems are available for indoor rooms and outdoor battery containers, designed with temperature-resistant and IP-rated components for harsh environments.

Traditional systems use water or CO₂, which are unsuitable for lithium-ion fires. BESS suppression uses clean agents or aerosol particles that absorb heat and interrupt combustion without damaging battery cells or electronics.

Routine 6-month inspections and annual system testing are recommended. Cylinders and detectors must be checked for pressure, signal function, and readiness.

Fire Engineering Technology’s BESS systems follow NFPA 855, NFPA 2001, UL 9540A, and IEC 62619 standards for battery energy storage fire protection.

Fire Engineering Technology provides custom-engineered, NFPA-compliant BESS fire suppression systems with design, installation, and maintenance support across India.

We integrate clean agent, aerosol, and inert gas solutions for maximum reliability, safety, and environmental compliance.

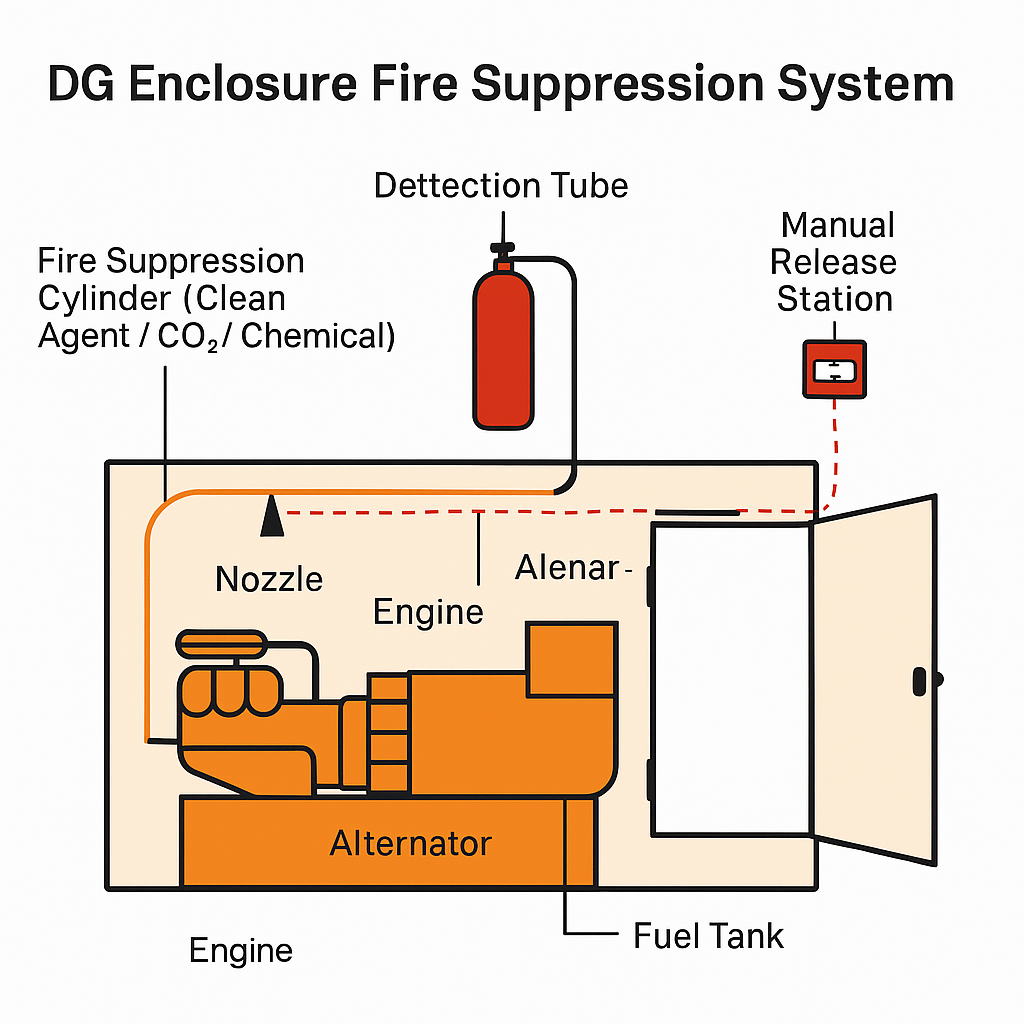

Fire Engineering Technology is a leading manufacturer and supplier of DG enclosure fire suppression systems in India. Our systems are designed to provide automatic, reliable, and maintenance-free protection for diesel generator (DG) sets, engine compartments, and generator enclosures — preventing catastrophic fire damage and equipment loss.

DG enclosures operate in confined spaces with high temperatures, flammable diesel, and electrical wiring — all of which pose significant fire hazards. Our automatic fire suppression systems are engineered to detect and extinguish fires instantly, ensuring zero downtime and continuous power supply.

We offer both clean agent and tube-based fire suppression systems specifically designed for DG rooms, generator housings, and acoustic enclosures.

The tube-based detection system uses a heat-sensitive polymer tube that bursts when it detects a temperature rise (110°C–150°C). This releases the extinguishing agent — FM-200, Novec 1230, CO₂, or Dry Chemical Powder — directly onto the fire.

The system is fully automatic, requires no external power, and is easy to retrofit in existing DG enclosures. It provides localized suppression directly at the ignition source (fuel line, exhaust, alternator, or engine).

Diesel Generator Enclosures

Engine Compartments & Alternators

Fuel Lines & Control Panels

Acoustic Enclosures & Power Backup Rooms

Industrial Plants & Commercial Buildings

✅ Fully automatic operation

✅ Compact and pre-engineered design

✅ Clean, residue-free suppression agents

✅ Fast response within seconds

✅ NFPA & UL compliant systems

✅ Easy installation and low maintenance

Fire Engineering Technology provides custom-engineered DG enclosure fire suppression systems with design, installation, and maintenance services across India — trusted by power plants, data centers, manufacturing units, and telecom facilities.

Protect your DG setup with Fire Engineering Technology’s automatic suppression system — built for safety, reliability, and performance.

A DG (Diesel Generator) Enclosure Fire Suppression System is an automatic fire protection system designed to detect and suppress fires in DG sets and engine housings using clean agent gases or tube-based detection technology.

Fires in DG enclosures can occur due to fuel leaks, hot exhaust surfaces, short circuits, or oil spills. These confined environments can ignite rapidly without early detection.

The system uses a flexible polymer tube installed inside the enclosure. When heat from a fire is detected, the tube bursts, releasing the extinguishing agent (FM-200, Novec 1230, or Dry Chemical Powder) directly onto the fire source — extinguishing it instantly.

FM-200 / Novec 1230 (Clean agents for electrical fires)

CO₂ systems (for large DG rooms)

Dry chemical systems (for fuel or oil-based fires)

Fully automatic & power-free operation

Quick activation within seconds

Zero residue & minimal downtime

Compact, maintenance-free design

Suitable for all DG sizes

Yes. All systems are designed as per NFPA 17, 2001, and 750 standards, ensuring maximum reliability and international safety compliance.

Because Fire Engineering Technology is a trusted Indian manufacturer of automatic DG enclosure fire suppression systems — offering tube-based, clean agent, and CO₂ solutions with nationwide installation and AMC support.

Our systems are proven across industrial, telecom, and energy sectors for superior fire safety and reliability.

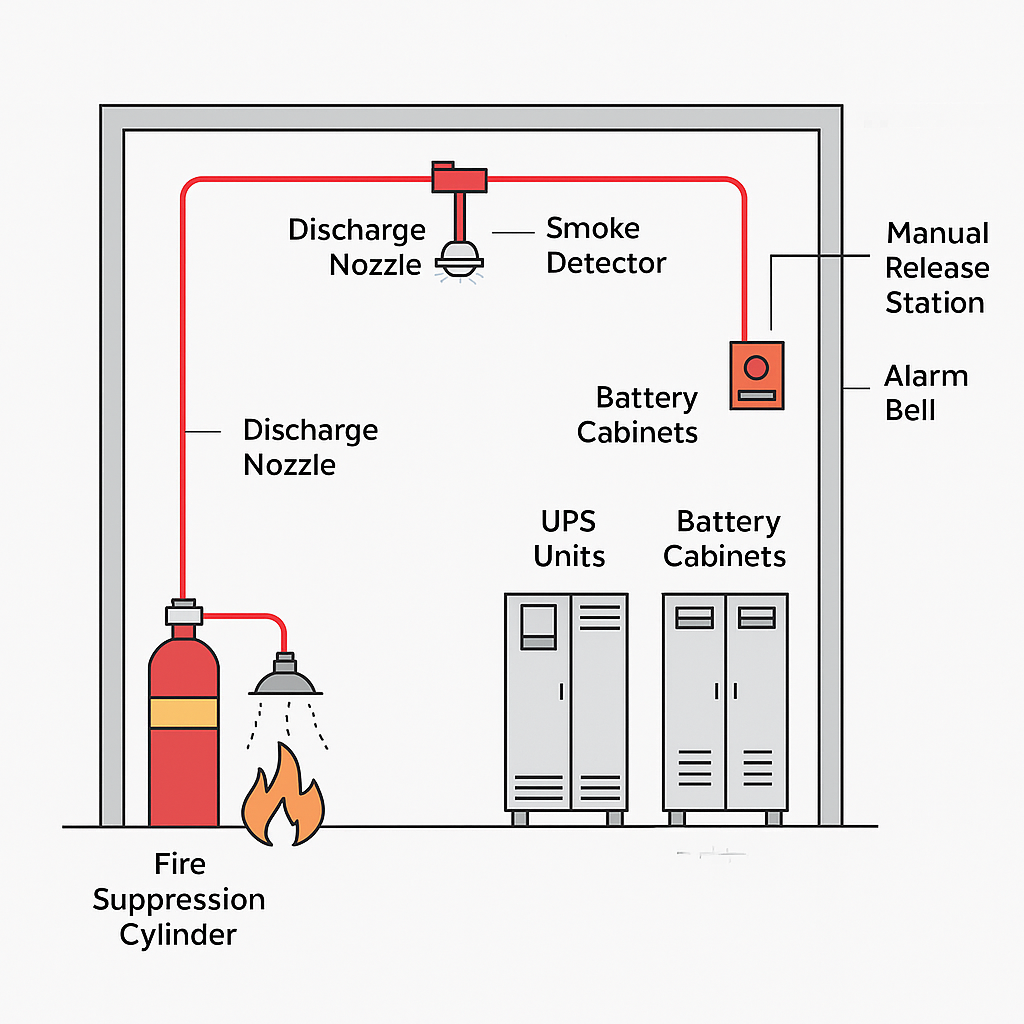

Fire Engineering Technology is a leading manufacturer and supplier of UPS Fire Suppression Systems in India, providing automatic, clean agent, and tube-based fire suppression solutions for UPS rooms, battery banks, and electrical enclosures.

A UPS (Uninterruptible Power Supply) room contains critical equipment and battery units that are prone to fire due to electrical faults, overcharging, or heat build-up. Our systems are engineered to detect fire early and extinguish it within seconds — ensuring zero downtime, equipment protection, and continuous power availability.

We offer multiple fire suppression system types for UPS and battery room protection, all designed to comply with NFPA 2001, NFPA 855, and ISO 14520 standards.

Uses FM-200 (HFC-227ea) or Novec 1230 gas for instant suppression of electrical fires. Ideal for UPS panels, battery rooms, and control cabinets.

✅ Safe for electronics

✅ No residue or cleanup required

✅ Fast discharge (<10 seconds)

Effective for large UPS rooms or electrical zones where total flooding is required.

✅ Non-conductive

✅ Cost-effective for large enclosures

✅ Requires room sealing and safety interlocks

Compact and self-activated system using flexible polymer heat-sensing tubes.

✅ Power-free operation

✅ Detects and suppresses fire directly at source

✅ Easy to install in UPS cabinets or electrical panels

Environmentally friendly, safe for human occupancy, and suitable for large battery installations.

UPS & Battery Rooms

Data Centers & IT Facilities

Power Distribution Panels

Telecom & Control Rooms

Solar & Renewable Energy Inverters

✅ 24×7 automatic protection

✅ Safe for electronic and battery equipment

✅ No residue, no downtime

✅ Environmentally friendly & NFPA compliant

✅ Designed for quick installation and long service life

A UPS Fire Suppression System is an automatic fire protection solution designed to detect and suppress fires in UPS rooms and electrical enclosures where overheating or battery malfunction can cause ignition.

UPS systems store high electrical energy and use batteries that generate heat during charging. Overheating, loose connections, or electrical faults can cause thermal runaway, leading to fire if not detected early.

Clean agent systems (FM-200 or Novec 1230) are best because they are non-conductive, residue-free, and safe for sensitive electronics. For small cabinets, tube-based systems are ideal.

Yes. All systems provided by Fire Engineering Technology are fully automatic and can be integrated with fire alarm and shutdown panels. They detect heat or smoke and discharge the extinguishing agent instantly.

Fast fire extinguishing

No damage to electronics

Eco-friendly and ozone-safe agents

Power-independent operation (tube-based type)

Compliance with NFPA and UL standards

UPS fire suppression systems are used in:

Data centers and server rooms

Industrial UPS & battery rooms

Telecom and solar power stations

Control panel cabinets

Fire Engineering Technology is India’s most trusted manufacturer and integrator of UPS and electrical fire suppression systems, offering FM-200, Novec 1230, CO₂, and tube-based solutions.

Our systems are tested, NFPA-compliant, and designed to protect critical UPS infrastructure with fast activation and long-term reliability.

Send Enquiry

Battery Energy Storage Fire Protection System for BESS provides automatic lithium-ion battery fire suppression, thermal runaway control and explosion prevention. Fire Engineering Technology delivers high-performance clean agent fire suppression solutions for BESS containers, battery rooms, ESS systems and industrial energy storage facilities.

The BESS Fire Suppression System is an advanced automatic fire suppression system specially designed for Battery Energy Storage Systems (BESS) to protect against lithium-ion battery fires, thermal runaway, short circuit, overheating and explosion risks. Developed by Fire Engineering Technology, this system provides fast, reliable and effective fire protection for battery storage containers, ESS rooms, solar power plants and inverter battery banks.

This high-performance battery fire suppression system uses clean agent fire suppression technology and tube-based fire detection and suppression to detect fire at the incipient stage and discharge instantly, preventing flame spread and minimizing damage to critical equipment. It is widely used in BESS containers, energy storage facilities, data centers, UPS rooms, EV charging stations and renewable energy plants for complete fire safety compliance.

Our BESS fire protection system is ideal for controlling thermal runaway in lithium-ion batteries, offering non-conductive, residue-free and environmentally safe suppression that ensures zero harm to sensitive electrical and electronic components. The system supports both automatic and manual activation, ensuring continuous monitoring and rapid response during emergencies.

With increasing demand for battery storage safety systems, the Fire Engineering Technology BESS Fire Suppression Solution ensures maximum reliability, low maintenance, long service life and compliance with international fire safety standards such as NFPA, UL and ISO norms. It is the perfect solution for industries seeking energy storage fire safety, battery room fire protection and automatic fire extinguishing systems for modern power infrastructure.

Send Enquiry

The UPS Fire Suppression System by Fire Engineering Technology is a specialized automatic fire protection solution designed to safeguard UPS panels, battery cabinets, power distribution units, and critical backup power infrastructure from fire hazards caused by overheating, short circuits, battery failure, arcing, and thermal runaway. The system ensures early fire detection and rapid suppression, minimizing downtime and protecting mission-critical operations.

UPS systems operate continuously under high electrical load and are vulnerable to:

Electrical short circuits

Battery overheating and thermal runaway

Cable insulation failure

Power electronics faults

A minor ignition inside a UPS cabinet can escalate quickly. Our UPS fire suppression system is engineered to detect and suppress fire at the incipient stage, before it spreads beyond the enclosure.

Heat-sensitive polymer detection tube installed inside UPS cabinet

Tube acts as detector + discharge nozzle

Direct agent release at fire source

Ideal for individual UPS panels and compact enclosures

Separate low-pressure cylinder with engineered nozzles

Detection using LHS cable, smoke detector, or heat detector

Suitable for large UPS cabinets, battery rooms, and multiple enclosures

Novec 1230 (FK-5-1-12) – eco-friendly, safe for occupied spaces

FM-200 (HFC-227ea) – fast-acting clean agent

CO₂ – for unoccupied or industrial UPS areas

All agents provide clean, residue-free fire suppression without damaging sensitive electronics.

Continuous monitoring of UPS cabinet temperature

Detection through tube rupture or detector signal

Automatic activation of suppression system

Rapid discharge of clean agent directly inside UPS enclosure

Fire suppressed within seconds with no residue

Automatic operation – no human intervention required

No water, no residue, no corrosion

Fast response time (early-stage suppression)

Compact design, easy retrofit

Minimal maintenance and long service life

Reduces downtime and equipment replacement cost

Designed and installed as per:

NFPA-2001 – Clean Agent Fire Suppression Systems

BIS / IS standards

IS 2189 (Fire Detection)

Insurance & statutory fire safety norms

Data centers & server rooms

Telecom facilities

Control rooms & command centers

Industrial plants

Hospitals, banks & commercial buildings

EV charging and energy storage facilities

Specialized expertise in UPS & electrical fire suppression

Proven DLP & ILP technologies

Custom-designed solutions for every UPS make and size

PAN-India installation & AMC support

Trusted manufacturer & system integrator

Choose UPS Fire Suppression System by Fire Engineering Technology for fast, reliable, and damage-free fire protection of your critical power infrastructure.

Send Enquiry

UL Approved Tube & Clean Agent Cylinder | Instant Fire Knockdown

INNOVEX® is a registered, UL compliant automatic fire suppression system designed to detect and suppress fire at its origin within milliseconds. Using a UL approved heat-sensitive detection tube and UL approved clean agent cylinder, INNOVEX delivers direct, residue-free fire suppression without electricity or human intervention.

Ideal for electrical panels, UPS systems, server racks, CNC machines, telecom cabinets, and enclosed industrial equipment, INNOVEX prevents costly damage, downtime, and fire escalation.

Detect Faster. Suppress Smarter. Protect Completely.

INNOVEX® is an automatic tube and cylinder based fire suppression system that detects heat or flame and releases clean agent directly onto the fire source within seconds.

Yes. INNOVEX uses a UL approved detection tube and UL approved / UL listed clean agent cylinder, ensuring international safety and reliability standards.

No. INNOVEX is a fully mechanical direct low pressure (DLP) fire suppression system and operates without power, batteries, or control panels.

INNOVEX supports FK-5-1-12 (Novec 1230 equivalent), FM-200 equivalent, and CO₂, selected as per application and safety norms.

It is ideal for electrical panels, MCC/PCC panels, UPS rooms, server racks, CNC machines, telecom cabinets, wind turbine panels, generators, and vehicle engine compartments.

Yes. The clean agents used are non-conductive, residue-free, and safe for sensitive electronics.

Send Enquiry