CO2 FLOODING ROOMS

Co2 flooding system for Electrical and storage area

Overview

Electrical control rooms, DG enclosures, and industrial storage areas face one of the highest fire risks due to energized circuits, cables, oils, and flammable materials.

Traditional fire extinguishing agents like water or foam cannot be used because they damage equipment or spread electrical hazards.

That’s where CO₂ Flooding Systems by Fire Engineering Technology become the safest, fastest, and most efficient solution.

Our CO₂ Fire Suppression Systems use high-pressure or low-pressure carbon dioxide gas to extinguish fires by displacing oxygen around the flame, stopping combustion instantly and leaving no residue.

We manufacture, install, and maintain NFPA-12 compliant CO₂ flooding systems across India for industrial, commercial, and electrical applications.

🧪 How the CO₂ Flooding System Works

When a fire is detected, the system automatically releases CO₂ gas stored in pressurized cylinders through a network of nozzles.

The carbon dioxide gas quickly reduces the oxygen concentration in the protected area to below 15%, making it impossible for combustion to continue.

Within seconds, the fire is extinguished without any damage to electrical or electronic components.

Once discharged, CO₂ dissipates harmlessly into the atmosphere, ensuring quick system reset and minimal downtime.

Working stages:

-

Fire detected by heat/smoke sensor or manual trigger

-

Activation signal opens the CO₂ cylinder valve

-

CO₂ gas floods the hazard zone uniformly

-

Fire extinguished within seconds

-

Pre-discharge alarm and delay ensure human safety

🧰 Types of CO₂ Flooding Systems

🔹 High-Pressure (HP) CO₂ System

-

CO₂ stored in 45 kg or 22.5 kg cylinders at ~55 bar pressure

-

Suitable for small to medium enclosures such as electrical panels, DG sets, transformers, MCC rooms, and control cabinets

-

Modular, compact, and easily expandable

🔹 Low-Pressure (LP) CO₂ System

-

CO₂ stored in a refrigerated bulk tank at ~20 bar pressure

-

Designed for large hazards or multiple connected rooms such as warehouses, conveyor systems, and storage plants

-

Economical for continuous or large-volume applications

⚡ Advantages of CO₂ Fire Suppression Systems

✅ Non-conductive – safe for live electrical installations

✅ Residue-free – no cleanup or contamination

✅ Fast discharge – extinguishes within seconds

✅ Total flooding – penetrates hidden spaces and cable voids

✅ Environmentally stable – CO₂ naturally occurring gas

✅ Low maintenance cost – easy cylinder handling and refilling

✅ Global compliance – NFPA-12 / ISO 6183 / IS 15519 standards

CO₂ systems are the most economical gaseous fire suppression systems for protecting electrical control panels, server rooms, battery banks, and industrial storage areas.

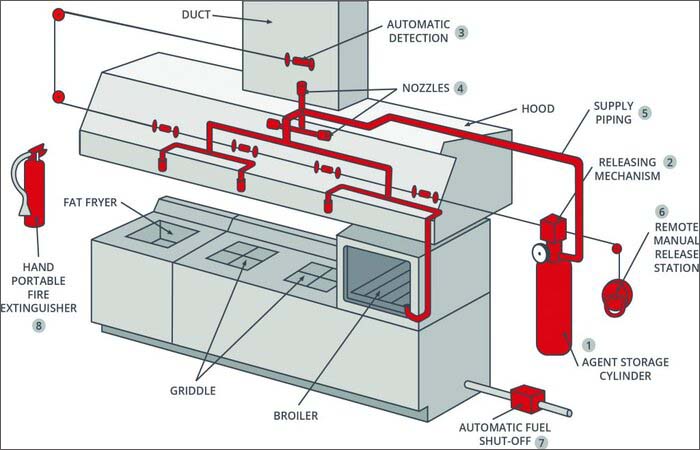

🧩 System Components & Design

A complete CO₂ Flooding System by Fire Engineering Technology includes:

| Component | Description |

|---|---|

| CO₂ Cylinders | High-pressure 22.5 kg or 45 kg cylinders filled with liquid CO₂ |

| Manifold Assembly | Distributes CO₂ from cylinder bank to discharge lines |

| Actuation Mechanism | Electrical, pneumatic, or manual activation |

| Discharge Nozzles | Designed for uniform CO₂ distribution and flow control |

| Control Panel | Manages detection, delay, alarms, and solenoid actuation |

| Detection Devices | Heat/smoke detectors or flame sensors |

| Safety Features | Time delay, pressure relief vents, evacuation alarms |

📐 System Design & Engineering Process

Every project by Fire Engineering Technology follows these NFPA-12 based steps:

-

Hazard Survey & Room Measurement

– Determine room volume (L × W × H), openings, and fire risk. -

CO₂ Quantity Calculation

– Compute required CO₂ mass (kg) for total flooding (usually 34–38% by volume). -

Cylinder Bank Design

– Select HP or LP cylinders based on storage capacity. -

Detection & Release Integration

– Link detectors to control panel with electrical or pneumatic actuation. -

Nozzle Layout Design

– Ensure uniform gas concentration throughout the protected area. -

Safety Interlocks

– Pre-discharge alarms, delay timers, ventilation shutdown, and evacuation sequence. -

Testing & Commissioning

– Hydro test, pressure test, and simulated discharge verification. -

Documentation & AMC

– Provide as-built drawings, test certificates, and maintenance schedule.

🏭 Applications

-

Electrical control rooms & switchgear rooms

-

DG sets & generator enclosures

-

Transformer and substation bays

-

Battery rooms & UPS enclosures

-

Data centers & server rooms

-

Industrial storage warehouses

-

Paint booths & chemical storage areas

-

Cable tunnels, conveyor systems, and turbine housings

Trending search terms: co2 flooding for electrical panel, co2 fire suppression for storage area, co2 system for transformer room, co2 fire protection for data center.

🧯 Technical Specifications

| Parameter | Value |

|---|---|

| Agent | Carbon Dioxide (CO₂) |

| System Type | Total Flooding / Local Application |

| Storage Pressure | 55 bar (HP) / 20 bar (LP) |

| Cylinder Capacity | 22.5 kg / 45 kg / 68 kg |

| Design Standard | NFPA-12 / ISO 6183 / IS 15519 |

| Discharge Time | < 60 seconds |

| Activation | Automatic / Manual / Pneumatic |

| Applications | Electrical & Storage Areas |

| Maintenance | Semi-Annual / Annual AMC |

| Manufacturer | Fire Engineering Technology (India) |

🚀 Why Choose Fire Engineering Technology

-

Certified Manufacturer of CO₂ fire suppression systems in India

-

Custom-engineered solutions for all types of electrical and industrial hazards

-

UL/FM-approved components and NFPA-compliant designs

-

Pan-India installation and AMC network

-

Quick CO₂ refilling & hydro testing services

-

Trusted by industries, PSUs, OEMs, and data centers nationwide

-

15+ years of field experience with 5000+ systems commissioned

🧠 Safety & Compliance

All systems include:

-

Pre-discharge alarms and sirens

-

Time delay for safe evacuation

-

Warning signage and manual release stations

-

Room venting to control over-pressure

-

Fire Department & Insurance documentation

Frequently Asked Questions (FAQ) – CO₂ Flooding System

1. What is a CO₂ Flooding System?

A CO₂ Flooding System is an automatic fire suppression system that uses carbon dioxide gas to extinguish fires by displacing oxygen around the combustion zone.

It works rapidly, leaving no residue or water damage, making it the ideal solution for electrical rooms, DG sets, transformer areas, and storage facilities.

2. How does a CO₂ Flooding System work?

When the fire detection system senses heat or smoke, it automatically triggers the release of CO₂ gas stored in high-pressure cylinders.

The CO₂ gas floods the protected area, reduces the oxygen level below 15%, and smothers the fire within seconds — without affecting electrical equipment or data.

3. Is CO₂ safe for electrical and electronic equipment?

Yes. CO₂ is a clean, non-conductive, and residue-free agent.

It causes no short circuits, corrosion, or residue, making it perfectly safe for control panels, switchgear rooms, data centers, battery rooms, and server racks.

4. What standards govern CO₂ Flooding System design?

All Fire Engineering Technology systems are designed and installed in accordance with NFPA-12, ISO 6183, and IS 15519 standards.

We also comply with local Fire Department NOC requirements and insurance approval norms for electrical and industrial applications.

5. What types of CO₂ systems are available?

There are two main system types:

-

High-Pressure (HP) CO₂ System: Uses 22.5 kg or 45 kg cylinders at 55 bar for small to medium hazards.

-

Low-Pressure (LP) CO₂ System: Uses refrigerated bulk tanks for large or multi-zone applications such as warehouses or storage areas.

6. Where can a CO₂ Flooding System be installed?

CO₂ Flooding Systems are ideal for:

-

Electrical control rooms and power panels

-

DG enclosures and generator rooms

-

Transformer and substation bays

-

Industrial storage and warehouses

-

Data centers and server rooms

-

Cable tunnels and conveyor systems

-

Paint booths and chemical storage zones

7. What are the main components of a CO₂ Flooding System?

A complete system includes:

-

CO₂ cylinders and manifold assembly

-

Actuation valves and release mechanisms

-

Discharge nozzles and distribution piping

-

Control panel with time-delay and alarm circuit

-

Detection system (smoke/heat sensors)

-

Safety devices – pressure relief vent, manual release, and warning signs

8. How much CO₂ gas is required for a room?

The CO₂ quantity depends on the room volume (m³) and application type (total flooding or local application).

According to NFPA-12, a total flooding system typically uses 34–38% CO₂ concentration by volume.

Fire Engineering Technology performs precise gas calculations and nozzle layouts for every project.

9. How fast does the CO₂ system discharge?

CO₂ is released and achieves full design concentration within 30–60 seconds, depending on system size and configuration.

This quick action ensures the fire is extinguished before it spreads or damages electrical components.

10. What safety features are included?

To protect personnel and ensure reliable performance, the system includes:

-

Pre-discharge alarms (audible & visual)

-

Time delay (allowing safe evacuation)

-

Ventilation shutdown interlock

-

Pressure relief venting to avoid over-pressure

-

Manual release & abort switch for emergency control

11. Can a CO₂ Flooding System be fully automatic?

Yes. Fire Engineering Technology designs fully automatic systems with detection, control panels, and solenoid-actuated discharge valves.

Manual backup activation and emergency abort options are also provided as per NFPA safety guidelines.

12. What are the benefits of CO₂ Flooding Systems over water or foam?

-

No electrical hazard — non-conductive

-

No cleanup — residue-free discharge

-

Quick extinguishment — within seconds

-

Zero damage to electrical/electronic assets

-

Compact & economical compared to clean-agent systems

13. How often should the CO₂ system be serviced or refilled?

-

Visual inspection: Monthly

-

Pressure check & testing: Every 6 months

-

Full system service: Annually or after discharge

Fire Engineering Technology offers comprehensive AMC (Annual Maintenance Contracts) for inspection, CO₂ refilling, hydro-testing, and system certification.

14. What happens after a CO₂ discharge?

After a discharge, the area should be ventilated before re-entry.

Our technicians will refill the CO₂ cylinders, test the system, and reset it for operation.

Downtime is minimal, and no equipment cleanup is required.

15. Can Fire Engineering Technology provide design, installation, and AMC across India?

Absolutely.

We provide end-to-end CO₂ fire suppression services — design, supply, installation, commissioning, refilling, and AMC — in Delhi NCR, Mumbai, Pune, Bengaluru, Hyderabad, Chennai, Ahmedabad, Kolkata, and all major industrial regions across India.

16. How do I get a CO₂ Flooding System quotation?

Simply call +91-9971365130 or email Info@fireengineeringtechnology.com to schedule a free site survey.

Our fire engineers will visit your site, assess your hazard area, calculate CO₂ requirements, and send a customized quotation with drawings and specifications.

✅ Summary

Fire Engineering Technology delivers certified CO₂ Flooding Systems that are fast, safe, reliable, and NFPA-compliant, protecting critical electrical installations, DG enclosures, and storage areas across India.

Call Now: +91-9971365130

Email: Info@fireengineeringtechnology.com

Protect. Prevent. Perform — with Fire Engineering Technology.