Fire CO2 gas flooding systems , Fire Protection system , Fire Protection & Suppression Systems , Fire Suppression System , Fixed fire fighting fire extinguishing system , Gas flooding systems , FIRE SUPPRESSION SYSTEM , Kitchen fire suppression system , Electrical Panels tube based automatic fire gas suppression system , Vehicle fire suppression system

15-Sep-2025

Key Benefits of Tube-Based Fire Suppression for Electrical Panels

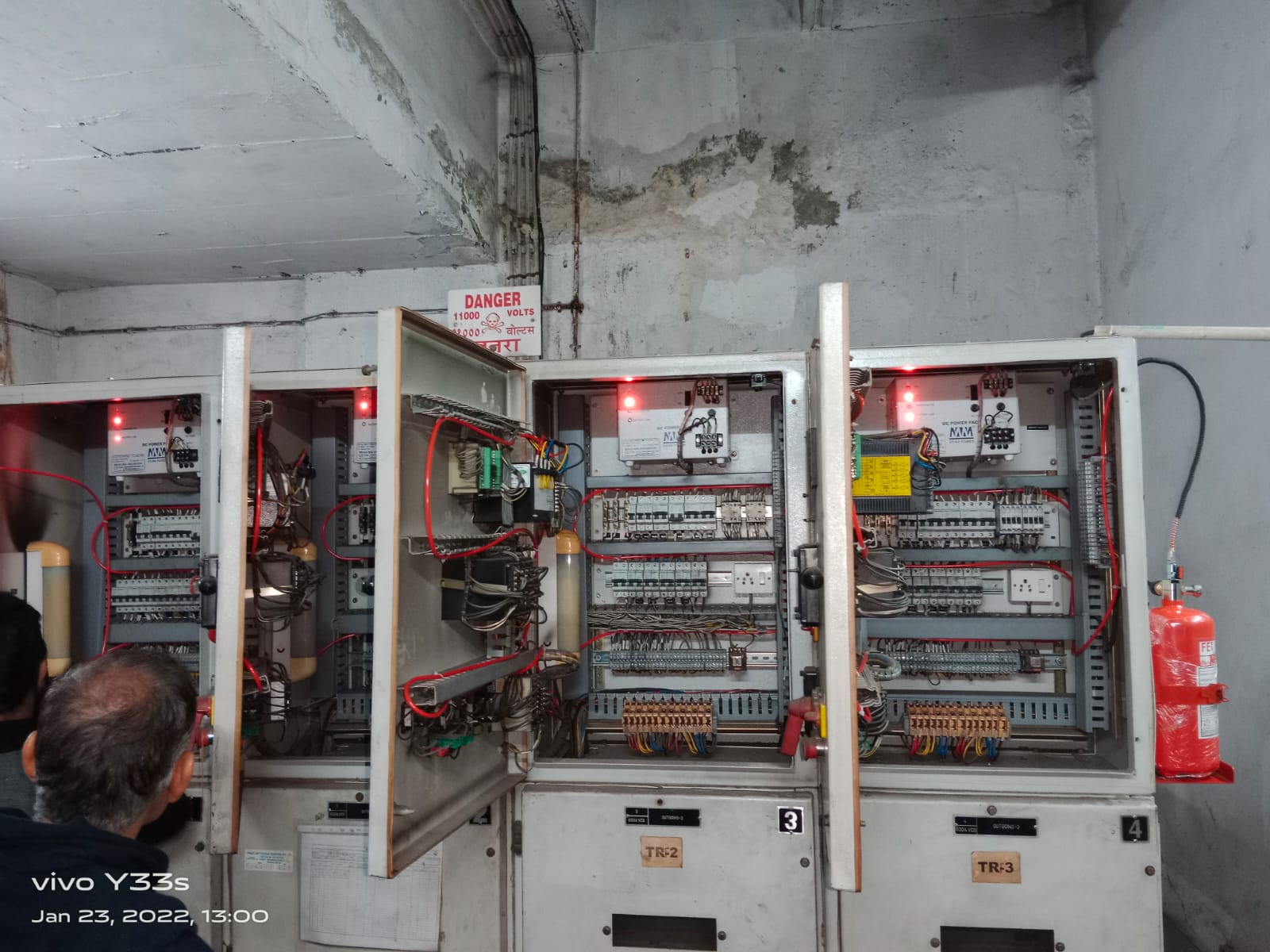

Electrical panel fires are a critical safety issue across Indian industries. A tube based fire gas suppression system offers automatic fire suppression with clean agents or CO2, providing gentle protection to sensitive electronics. These systems are NBC 2016-compliant and follow NFPA 2001 guidelines for clean agent electrical cabinet suppression.

In India, electrical panels are the backbone of industrial and commercial power distribution. From MCC (Motor Control Centers) and PCC (Power Control Centers) to inverter and UPS panels, these enclosures operate continuously under high load. However, they are also one of the leading sources of fire incidents in factories, offices, and data centers.

Short circuits, loose terminations, overloads, and arc faults inside panels often escalate into electrical fires, causing heavy equipment damage, downtime, and safety risks. To prevent such losses, tube based fire gas suppression systems are increasingly being adopted by electrical panel manufacturers and users across India.

Fire Engineering Technology offers advanced suppression solutions that combine automatic detection, instant suppression, and compliance with fire safety norms.

A tube based suppression system is an automatic fire detection and suppression solution designed for confined enclosures like electrical panels.

Detection: A special flexible polymer tube is installed inside the panel.

Activation: When exposed to heat or flame, the tube ruptures at the hottest point.

Suppression: The connected cylinder discharges suppression gas (Clean Agent FK-5-1-12, HFC-227ea, or CO2) directly at the fire source.

Result: Fire is suppressed instantly, with no collateral damage to equipment.

Electrical panel builders are increasingly integrating tube suppression systems to make their panels safer and more compliant with customer demands. By doing so, they:

? Offer value-added panels with built-in fire protection.

? Meet Indian and global safety standards.

? Provide industries with fire-safe electrical enclosures that reduce downtime.

? Gain a competitive edge in high-risk industries like IT, power, renewable energy, telecom, and manufacturing.

To ensure compliance, manufacturers and users must follow recognized fire safety standards:

National Building Code of India (NBC 2016 – Part 4 Fire & Life Safety)

Recommends automatic fire suppression systems for critical electrical rooms and enclosures.

Stresses on clean agent systems for electrical equipment due to their non-conductive nature.

NFPA 2001 (Clean Agent Fire Extinguishing Systems)

Internationally accepted guideline for clean agent systems inside enclosures like panels and control cabinets.

NFPA 70 (National Electrical Code)

Recommends protection for electrical control equipment to prevent arc-flash and fire hazards.

IS/IEC 60364 & IS 2189 (Indian Standards for Fire Detection and Suppression Systems)

Support the use of automatic suppression in electrical installations.

By adopting tube based suppression systems, electrical panel manufacturers and users in India not only comply with NBC and NFPA recommendations but also create a safer, norm-compliant environment for operations.

Data Centers & IT Parks – Fire safety for UPS panels, server racks, and control cabinets.

Manufacturing & Automotive – MCC and PCC panel protection for automation lines.

Renewable Energy & Power – Inverter panels, BESS, and solar control boards fire suppression.

Telecom Infrastructure – Safety for BTS station panels and switching cabinets.

Commercial Buildings – Distribution boards and LT/HT panels fire protection.

Automatic & Fast – Detects and suppresses fire at the source.

Localized Action – Protects the panel without flooding the entire room.

Residue-Free – Clean agents cause no damage to electronics.

Norm-Compliant – Meets NBC 2016, NFPA, and IS guidelines.

Compact & Easy to Install – Fits easily in small enclosures.

Eco-Friendly Options – FK-5-1-12 agent is sustainable and people-safe.

At Fire Engineering Technology, we specialize in automatic tube based fire suppression systems for electrical panels. Our systems are:

?? Designed to meet Indian NBC 2016 norms and NFPA standards.

?? Available in both Clean Agent and CO2-based options.

?? Certified, reliable, and easy to retrofit in existing panels.

?? Widely adopted by electrical panel manufacturers across India.

By installing our tube based suppression system, you ensure continuous protection, norm compliance, and peace of mind.

Electrical panel fires are a major fire hazard in Indian industries, but they can be prevented with the right solution. Tube based fire suppression systems provide automatic detection, instant suppression, and compliance with NBC 2016 and NFPA 2001 standards, making them the ideal choice for manufacturers and users.

?? With Fire Engineering Technology, you not only secure your panels but also align with the highest fire safety norms in India.

fire suppression India

electrical panel fire suppression

tube based fire suppression

clean agent fire suppression

automatic fire suppression panels

NBC 2016 fire safety panels

NFPA fire suppression electrical cabinet

electrical cabinet fire suppression system

gas suppression system India

CO2 electrical panel fire protection

tube based fire gas suppression system for control panels India

automatic clean agent suppression system for MCC PCC panels

NBC 2016 compliant fire suppression system for electrical panels

NFPA 2001 clean agent suppression for electrical cabinets

heat detection tube fire suppression for electrical enclosures

CO2/inert gas electrical panel fire protection system

best fire suppression system for electrical panels in India

electrical panels fire safety norms NBC & NFPA compliance

Fire Engineering Technology electrical panel fire suppression

fire suppression system manufacturers in India for electrical panels

A tube based fire suppression system is an automatic fire safety solution that uses a flexible polymer detection tube installed inside enclosures like electrical panels. When exposed to high heat or flame, the tube bursts and releases a suppression agent (Clean Agent or CO2) directly at the fire source, extinguishing it instantly.

The system works on a heat-sensitive pressurized detection tube connected to a gas cylinder. When fire starts:

Tube senses heat at the exact ignition point.

Tube ruptures automatically at ~110–150°C.

Gas agent discharges directly onto the fire.

Fire is extinguished within seconds, preventing damage.

Electrical panels are confined enclosures where fires can spread rapidly due to wiring faults. Tube systems are:

Automatic (no manual intervention needed).

Compact (fits inside panels).

Safe (clean agents are non-conductive & residue-free).

Cost-effective compared to total flooding systems.

At Fire Engineering Technology, we offer tube systems with:

Clean Agents (FK-5-1-12, Novec 1230, HFC-227ea) – safe for electronics, eco-friendly.

CO2 (Carbon Dioxide) – effective for small enclosed panels but requires caution in occupied spaces.

Yes ?. Our systems follow:

NBC 2016 (Part 4 – Fire & Life Safety, India) recommendations for electrical fire protection.

NFPA 2001 (Clean Agent Fire Extinguishing Systems).

IS 2189 & IS/IEC standards for detection and suppression.

This ensures reliability and compliance with both Indian and international fire safety standards.

Yes. Fire Engineering Technology designs systems that are easy to install in both new and existing panels, making them highly suitable for retrofitting in factories, data centers, and commercial buildings.

They are widely used across:

Data centers & IT parks

Manufacturing & CNC machines

Renewable energy (solar, wind, BESS)

Power plants & substations

Telecom BTS & switching stations

Commercial buildings & offices

With proper maintenance, the detection tube lasts 8–10 years, while the suppression cylinders may require hydro-testing and refilling every 5 years as per safety norms.

We recommend annual inspections to check pressure, integrity of the detection tube, and agent levels. Fire Engineering Technology provides AMC (Annual Maintenance Contracts) for hassle-free compliance.

Fire Engineering Technology supplies systems in multiple sizes (2kg, 4kg, 6kg, 9kg, etc.), depending on the panel volume and fire risk. Custom solutions are also available for large enclosures.

Clean Agent: Best for sensitive electronics (IT, data centers, control panels).

CO2: Suitable for small enclosed panels in unoccupied areas.

?? Fire Engineering Technology helps clients choose the best suppression agent based on industry, risk level, and norms.

Compared to room flooding systems, tube suppression is affordable, requires less infrastructure, and reduces downtime. It directly protects the source of fire instead of covering the whole room, making it highly cost-efficient.

No. Tube suppression systems complement extinguishers. They provide automatic protection inside panels, while extinguishers are required for manual intervention in surrounding areas.

No. Fire Engineering Technology provides eco-friendly clean agent systems (like FK-5-1-12) that have zero ozone depletion potential and are safe for occupied areas.

Leading Indian manufacturer of automatic fire suppression systems.

NBC 2016 & NFPA compliant designs.

Available in Clean Agent & CO2 options.

Proven track record across data centers, manufacturing, and energy sectors.

Reliable after-sales service and AMC support nationwide.

These systems protect MCC panels, PCC panels, LT/HT distribution boards, VFD panels, control panels, battery panels, inverter panels, and UPS enclosures. Fire Engineering Technology customizes suppression systems for each type.

While not always mandatory, NBC 2016 and IS/IEC guidelines strongly recommend automatic suppression for critical electrical enclosures. Many industries now adopt tube systems to meet insurance and audit requirements.

Direct Release: The tube itself bursts and discharges the gas directly at the fire.

Indirect Release: The tube acts as a detection line, triggering discharge from nozzles.

?? Fire Engineering Technology offers both types depending on panel design and size.

Yes. Our systems can be interfaced with fire detection and alarm panels (FACP), providing remote monitoring, alarms, and signals for shutdown of equipment.

Installation is quick and non-intrusive. A typical MCC or control panel can be equipped within 2–3 hours without disturbing operations.

Yes. Clean Agent systems (FK-5-1-12, HFC-227ea) are people-safe and environmentally friendly. CO2 systems are suitable for unoccupied enclosures only.

Sprinklers: Water-based, not suitable for electrical fires.

Room Flooding: Protects the entire room, costly and requires sealing.

Tube Based: Protects only the electrical enclosure, affordable and efficient.

Yes, but panels must be weather-sealed enclosures. Fire Engineering Technology supplies tube systems with UV and temperature-resistant tubing for outdoor installations.

Our systems comply with:

UL-listed clean agents

CE-certified components

NBC 2016 recommendations

NFPA 2001 & IS 2189 standards

Yes ?. Many insurers encourage automatic suppression inside electrical panels as it reduces claims. Having a Fire Engineering Technology system may help in premium reduction.

Even small enclosures of 0.1m³ volume can be protected. Systems are scalable for panels up to several cubic meters in volume.

Yes. With indirect release systems, one cylinder can protect multiple panels using branched tubing and nozzles. Fire Engineering Technology engineers design such solutions for large facilities.

The fire is suppressed instantly. The tube needs to be replaced, and the cylinder must be refilled. Fire Engineering Technology provides recharging and service support across India.

It depends on:

Panel volume (m³)

Fire risk category

Suppression agent type

Our engineers provide detailed design & calculation as per NFPA and IS standards.

They are highly reliable with >95% success rate in extinguishing electrical fires at the source. Fire Engineering Technology systems are tested, certified, and proven in Indian industrial environments.

Yes. They are ideal for battery racks, lithium-ion battery cabinets, and UPS panels, offering quick protection against thermal runaway fires.

Cost varies by panel size, agent type, and number of enclosures. Typically, systems start at affordable pricing per panel compared to room flooding solutions. Fire Engineering Technology provides cost-effective packages for OEMs and end-users.

No. They are fully mechanical and operate without any external power supply, ensuring protection even during electrical failures.

Yes. We work with electrical panel manufacturers in India to provide pre-fitted fire suppression systems, enhancing product safety and market value.

Electrical panel fires remain one of the leading causes of industrial fire incidents in India, often resulting in heavy equipment loss, downtime, and safety hazards. Traditional methods like sprinklers or extinguishers are not suitable for confined electrical enclosures, which is why tube based fire suppression systems have become the industry standard.

With automatic detection, direct suppression at the fire source, and compliance with NBC 2016, NFPA 2001, and IS 2189 norms, these systems provide unmatched reliability and protection. They are compact, cost-effective, eco-friendly, and can be easily retrofitted into new or existing electrical panels.

For electrical panel manufacturers, adopting tube suppression systems means delivering value-added, fire-safe products to customers. For end-users, it ensures uninterrupted operations, reduced fire risk, and peace of mind.

At Fire Engineering Technology, we specialize in advanced tube based fire suppression solutions designed for India’s industries, from data centers and telecom to renewable energy, manufacturing, and power distribution. Our systems are engineered for maximum safety, fast action, and long-term reliability.

?? Conclusion in one line:

Using a tube based fire suppression system is not just a safety upgrade—it is a necessity for protecting electrical panels, ensuring compliance, and safeguarding business continuity in India.

Want to know more about our products.. fill the form below