Fire Fighting system , Fire Safety Systems , Fire Protection and Suppression Systems , Electrical fire suppression System , Fire Suppression System , FIRE SUPPRESSION SYSTEM , Indirect Low Pressure Fire Suppression System Technology , Firetrace - Tube based gas suppression system , Electrical Panels tube based automatic fire gas suppression system

16-Jan-2026

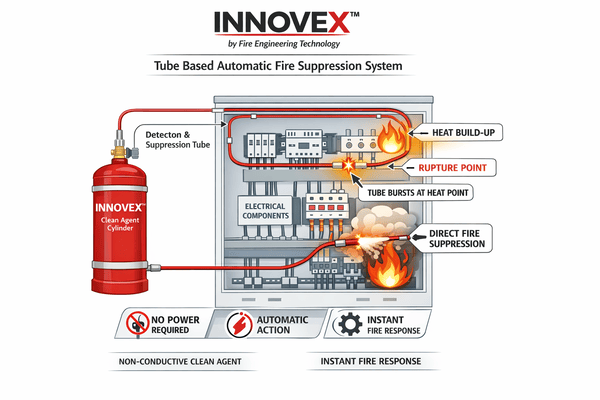

INNOVEX™ is an advanced tube based automatic fire suppression system designed to redefine the future of electrical fire protection. Engineered by Fire Engineering Technology, INNOVEX combines smart detection, instant suppression, and UL approved reliability to protect critical electrical assets without human intervention.

Built for modern electrical risks, INNOVEX represents the next generation of automatic fire suppression systems for electrical panels, control cabinets, MCC panels, server racks, EV chargers, UPS systems, and power distribution boards.

Smart Automatic Activation – Detects heat and flame at the source and suppresses fire instantly

Tube Based Technology – No sensors, no wiring, no external power required

UL Approved Fire Suppression System – Trusted global safety and performance standards

Non Conductive Clean Agent – Safe for sensitive electrical and electronic equipment

Zero Downtime Protection – Prevents fire escalation before damage occurs

Compact In Cabinet Design – Ideal for enclosed electrical panels and control rooms

Maintenance Friendly & Cost Effective – Long service life with minimal upkeep

Electrical Panels & Switchgear

PLC, MCC & Control Panels

Data Centers & Server Racks

EV Charging Stations

Telecom Cabinets

UPS & Battery Energy Storage Systems

Industrial Automation Panels

As electrical infrastructure becomes smarter and more compact, traditional fire protection methods fall short. INNOVEX™ Smart Tube Based Suppression System aligns with the future by delivering early detection, localized suppression, and automatic fire response — all in one intelligent solution.

tube based fire suppression system, UL approved fire suppression system, automatic electrical fire suppression, smart fire suppression system, electrical panel fire protection, in cabinet fire suppression system, clean agent fire suppression, electrical fire safety system, automatic fire extinguisher for panels, future fire suppression technology, electrical panel fire suppression India, smart automatic fire suppression system, electrical cabinet fire protection, advanced fire suppression systems

Smart Protection. Automatic Response. Future Ready Fire Safety.

INNOVEX™ is a UL approved tube based automatic fire suppression system designed for electrical panels, control cabinets, MCC panels, server racks, UPS systems, EV chargers and industrial enclosures. Developed by Fire Engineering Technology, it provides smart heat detection and instant fire suppression at the source without sensors, wiring or power. Using a clean agent, non conductive and residue free technology, INNOVEX ensures fast response, zero downtime, low maintenance and future ready electrical fire protection.

Want to know more about our products.. fill the form below