Fire Fighting system , Fire Safety Systems , Fire Protection system , Fire Protection Systems , Fire Protection and Suppression Systems , Fire Suppression System , Kitchen fire suppression system

22-Sep-2025

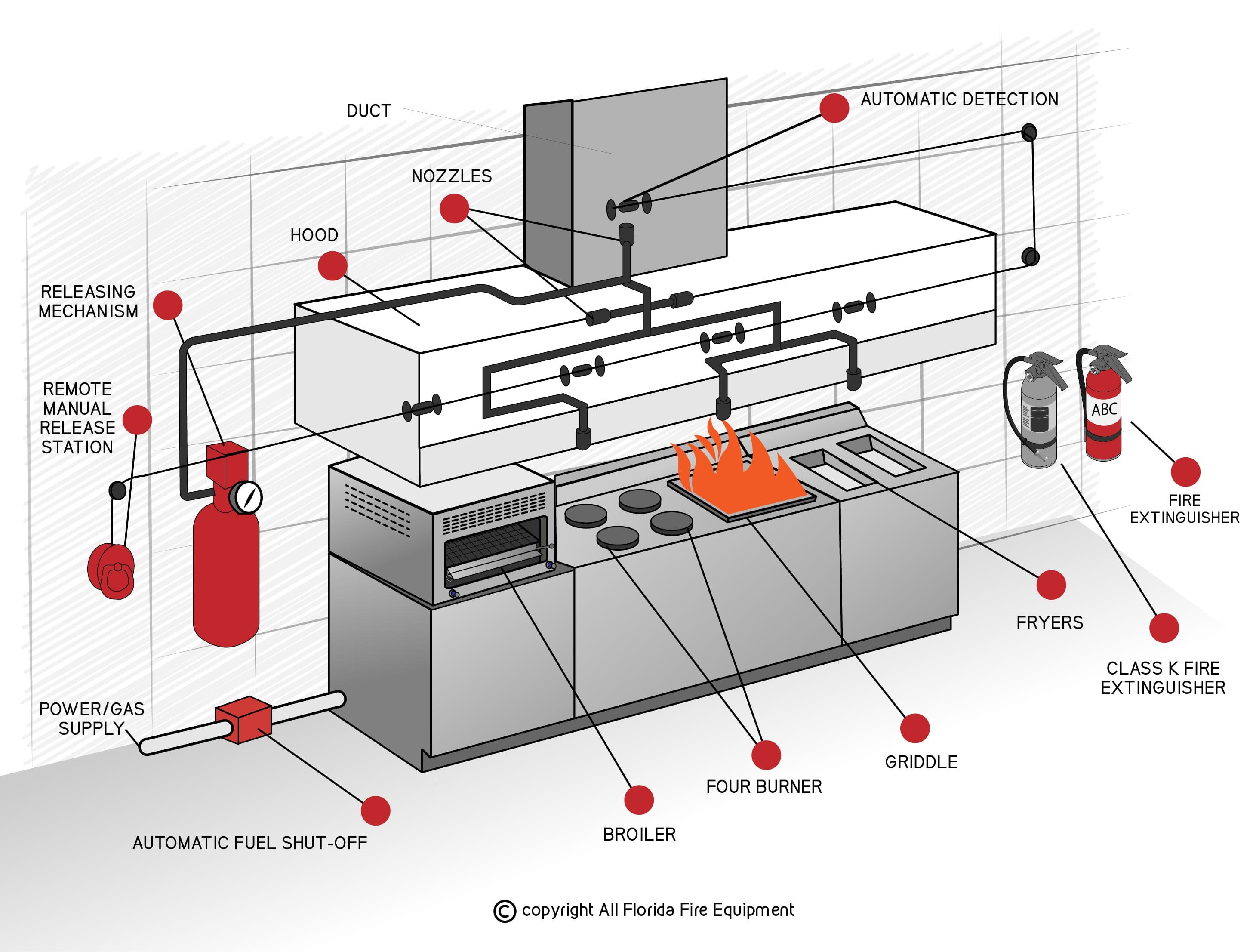

Automatic kitchen fire suppression systems are engineered systems installed over cooking equipment (ranges, fryers, grills etc.), exhaust hoods, ducts, and grease removal devices to detect a fire (e.g. via fusible links or heat sensors), suppress it (via extinguisher agent—usually wet chemical), shut off fuel/electric sources, and prevent re-flash. These systems are typically designed as UL-listed or equivalent, to standards like NFPA (in the U.S.) or local equivalents.

Grease fires spread fast, especially via ducts and hood plenums.

Manual extinguishers often fail (visibility, speed, operator error).

Automatic suppression can save lives, reduce property damage, reduce insurance costs, and help satisfy legal and insurance requirements.

Detection mechanism

Fusible links, heat sensors, or both.

Sometimes flame or optical sensors in more advanced systems.

Agent chamber & piping/nozzles

Wet chemical agent (typical for grease cooking).

Nozzles placed to cover cooking surfaces, hood interior, grease filters, ducts as needed.

Fuel & power shut-offs

Gas valves / electric cut-offs that are tied into system activation.

Makeup air shutdown sometimes also required.

Manual activation

Pull station or actuator, even if system is automatic, for cases when automatic does’t trigger (or system is off).

Audible/visual alarms

Alert kitchen staff and management when system activates.

Often integrated with fire alarm system.

Hood and duct structure & grease removal

Correctly sized hoods, grease filters, duct materials.

Regular cleaning (filters, ducts) to reduce buildup, which can block suppression or make fire worse.

(These refer mainly to U.S./NFPA; many jurisdictions have similar or adapted codes.)

NFPA 96: Standard for Ventilation Control and Fire Protection of Commercial Cooking Operations. It sets requirements for exhaust hoods, ducts, grease removal, cleaning, automatic extinguishing, etc.

NFPA 17A: Standard for Wet Chemical Fire Extinguishing Systems. This standard governs pre-engineered wet chemical systems commonly used over cooking equipment. It includes requirements for design, installation, inspection, testing, and maintenance.

ANSI/UL-300 requires that automatic fire-extinguishing systems for commercial cooking equipment be tested in certain ways, have certain shut-off capabilities, etc. All systems in certain jurisdictions must be UL300-listed.

Authority Having Jurisdiction (AHJ): local fire codes, building codes, health department, insurance may all require submission of plans, inspections, approvals. It is essential to check with AHJ before design/installation.

Inspection / Testing / Maintenance

Semi-annual inspections of suppression systems, ducts, hoods.

Cleaning schedule for grease removal devices / ducts depending on volume / type of cooking: monthly, quarterly, semiannually etc.

Operation instructions (manual operation) posted, staff trained, records kept.

Here is a recommended process (from a manufacturer perspective) for installing an automatic kitchen fire suppression system:

| Step | What to Do | Why It Matters |

|---|---|---|

| 1. Risk assessment / site survey | Evaluate kitchen size, cooking appliances, layout, fuel types, exhaust system, hood structure, grease duct path, electrical layout. Determine what areas need protection (hood interior, filters, ducts, cooking surfaces). | Determines the correct system type, number and location of nozzles, detection mechanisms, capacity. |

| 2. Selecting suitable equipment | Choose a pre-engineered wet chemical system certified to UL-300 / equivalent, with the correct agent, capacities; proper nozzles; shut-off devices; manual actuation; alarms. | Ensures fire suppression will function correctly when needed. |

| 3. Plan & design (with AHJ approval) | Prepare system layout drawings showing hood, ducts, nozzles, piping, shut-offs, detection points, manual pull stations. Submit to local fire department / building authority for approval. | Required by code to ensure compliance; avoid rework or legal penalties. |

| 4. Physical installation | Install the hood, ductwork, piping, nozzles, agent cylinder, detection system, shut-offs. Ensure wiring/piping are properly supported, materials compatible, clearances maintained. Install manual activation device at required height. | Correct installation ensures system reliability and legal compliance. |

| 5. Integration of power/fuel shut-offs | Tie in gas valves, electric power to system for automatic shutdown; makeup air and exhaust fan interlocks; ensure safety interlocks. | Prevents fire spreading via fuel supply or ventilation draft. |

| 6. Commissioning / Testing | After installation: test detection, discharge, alarms, shut-offs; simulate activation. Obtain AHJ inspection & approval. | Ensures that system works under real conditions; required before operation. |

| 7. Staff training & signage | Train staff how to respond, where is the manual pull, what to do after activation; post instructions; make sure everyone knows. | In emergencies, correct responses save lives. |

Costs vary widely depending on country, size, cooking operations, system type, materials, labor, etc. Below are ballparks (primarily U.S., but useful for comparative purposes) plus factors affecting cost.

| Type of Kitchen / Size | Typical Cost Range* |

|---|---|

| Small restaurant / café hood over moderate cooking equipment | INR 2,500 - 6,0000 for a basic wet chemical hood suppression system. |

| Larger restaurants, multiple hoods, complex ductwork, special fuel types | Costs go higher depending on number of nozzles, complexity of shut-offs, bigger agent cylinders, integrated alarms, higher labor. Possibly INR 7,0000-15,0000+ or more. |

| Retrofit installations | Cost increases due to access, modifications, piping routing, structural adjustments. Possibly 30-100% higher than new installation. |

* These are U.S. costs; in India or other countries, material sourcing, labor cost, regulatory fees may change these numbers significantly (often lower labor, but imported equipment or certification can add cost).

Other cost factors:

Number of nozzles & complexity of duct layout

Type & size of suppression agent cylinder

Shut-off valves for the fuel (gas/electric) and their automation or interlock systems

Hood & duct fabrication or modification if needed

Electrical work (alarms, wiring, sensors)

Permits, plan review fees, inspections by authority

Environmental and safety compliance (e.g. disposal of agent, ventilation requirements)

Ongoing maintenance & periodic inspections, cleaning costs

To ensure compliance, maintain safety, and avoid liabilities, a manufacturer-oriented checklist might look like this:

Check local codes & standards

Is it NFPA 96 / NFPA 17A / UL-300 or local equivalent?

Is there a law/mandate in your city-municipality requiring hood suppression for kitchens above certain size / business type?

Check listing / certification of components

Suppression system must be UL-listed (or local equivalent) for that application.

All nozzles, sensors, fusible links, cylinders must be certified.

Submission and approval by AHJ

Drawing approval before installation.

Inspections during and after installation.

Proper installation practices

Correct clearances.

Proper support for piping.

Manual pull station in specified location & height.

Shutdowns for gas/electric/make-up air.

Signage & instructions

Posted manual activation instructions.

Operational signage.

Staff training

Maintenance, cleaning, inspections

Schedule semi-annual or more frequent inspections.

Clean hoods, filters, grease ducts according to code intervals.

Testing of detection devices, nozzles, shut-offs, alarms, etc.

Record keeping

Logs of inspections, cleaning, maintenance.

Certificates from installers.

Keep design drawings updated.

Insurance/ liability compliance

Ensure the system is acceptable to your insurance provider.

Possibly lower premiums once system installed & maintained.

Routine inspections: check fusible links / sensors, check agent cylinder pressure/status, check for obstructions or dirty filters, ensure no pipe/nozzle damage.

Cleaning: grease filters daily or as needed; hood interior; ducts regularly (monthly/quarterly etc per type of cooking).

Testing: mimic activation (without discharge) or test sensors, ensure that shut-offs work, alarms are heard/seen.

Refilling / servicing: after any discharge, or if parts wear out.

Documentation: as above.

If building / selling suppression systems, manufacturers should ensure:

Clear installation manuals, with updated guidance per current relevant standards.

Training and certification programs for installers.

Designing for ease of maintenance (access to nozzles, ability to service fusible links).

Quality of materials (using corrosion-resistant materials for piping, high-quality detectors).

Providing parts, maintenance plans, replacement components.

To illustrate, here’s a simplified example:

A restaurant with one 8-ft hood over a range + deep fryer + char-grill. Custom hood & duct run of length ~ 12 ft, with filters.

A wet chemical suppression system UL-300, with 4 nozzles (range, fryer, griddle, duct), one fusible link detection + manual pull station, gas shut-off valves.

Installation cost: agent chamber with cylinder (~USD 1,500), piping/nozzles (~USD 1,000), hood/duct fabrication or adjustment (~USD 2,000), electrical and interlocks (~USD 800), labor (~USD 1,200), approval & permit fees (~USD 500). Total ~ USD 7,000. Ongoing cleaning & inspections ~ USD 500-1,000/year.

Retrofitting old kitchens: routing pipes, adding manual pull, ensuring gas/electric shut offs may be tricky.

Under-estimating cooking load: more grease, higher heat => more frequent cleaning, more robust system.

Neglecting duct/housing cleaning => system performance degraded or fire spread beyond coverage.

Non-compliance with newer versions of code (e.g. UL-300, updated NFPA) leading to rejected inspections.

Ignoring staff training => even with system, poor response can cause damage or injury.

Reduced risk of loss (property, business interruption).

Lower insurance premiums in many cases.

Less downtime after fire incidents.

Protection of staff and customers, better public reputation.

If you are in India (or another non-U.S. setting), consider:

Local fire safety laws / regulations: The National Building Code of India (NBC), Fire Service Acts in states, local municipality fire guidelines.

Are wet chemical suppression systems certified locally or must be imported? Are equivalents to UL recognised, or do you need BIS (Bureau of Indian Standards) or local laboratory certification?

Local utilities: gas supply shut-off, electric supply disconnection.

Cost of imports (agent, cylinders) and skilled labor.

Want to know more about our products.. fill the form below