Fire Fighting system , Fire Safety Systems , Fire Protection Systems , Fire Protection & Suppression Systems , Fire Suppression System , FIRE SUPPRESSION SYSTEM , Indirect Low Pressure Fire Suppression System Technology , Firetrace - Tube based gas suppression system , Electrical Panels tube based automatic fire gas suppression system

01-Dec-2025

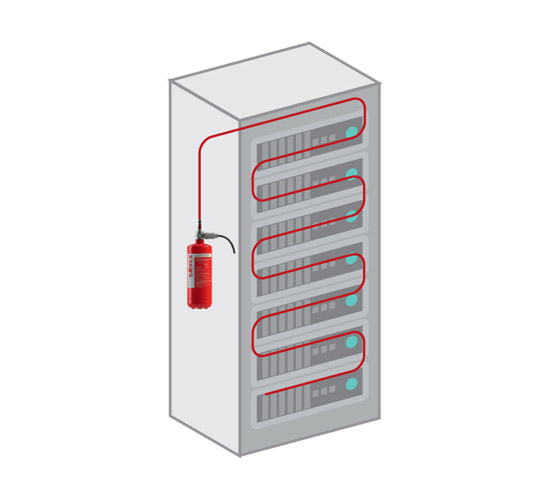

The Indirect Low Pressure (ILP) Fire Suppression System for Server Racks provides fast, automatic, and damage-free fire protection for high-value IT and data center infrastructure. This system uses clean agent fire suppression technology combined with advanced heat detection, ensuring early fire suppression directly at the source.

In an ILP fire suppression system, the extinguishing agent such as Novec 1230, FM-200, or CO2 is stored in a low-pressure cylinder and released indirectly through discharge nozzles upon activation. Fire detection is achieved using Linear Heat Sensing (LHS) cable, smoke detectors, or heat detectors installed inside the server rack. When abnormal temperature rise or smoke is detected, the system triggers immediate agent discharge inside the rack enclosure.

The server rack ILP fire suppression system effectively suppresses Class A, B, and C fires without water, residue, or harm to sensitive electronics. Designed as per NFPA-2001, BIS, and ISO standards, it is ideal for data centers, server rooms, network racks, UPS cabinets, telecom racks, and control rooms, ensuring minimal downtime, high reliability, and continuous business operation.

Unlike the direct system where the tube itself bursts and releases the agent, the Indirect Low Pressure (ILP) system uses the heat-sensing tube only for fire detection, not for agent discharge.

The tube detects the fire by bursting at the hottest point.

Instead of releasing the agent through the tube, the rupture activates a separate nozzle network.

The agent is discharged through pre-engineered nozzles, ensuring uniform suppression across the entire rack.

This makes the ILP system ideal when you require broader coverage, multi-rack protection, or precise agent flow control.

Detection via Polymer Tube

A heat-sensing tube runs throughout the rack. When fire temperature reaches ~150–180°C, the tube bursts.

System Activation

The burst causes a pressure drop inside the system, triggering the valve mechanism of the agent cylinder.

Agent Release Through Nozzles

The extinguisher agent flows through dedicated stainless-steel nozzles positioned inside the server rack.

Total Flooding Inside the Rack

The entire internal space of the rack is filled with clean agent, extinguishing the fire in seconds.

This method ensures complete enclosure protection, making ILP suitable for larger or complex rack layouts.

Fire Engineering Technology offers multiple safe and effective agents:

FK-5-1-12 (Novec Equivalent) – Ideal for IT hardware, leaves no residue

HFC-227ea – Widely used clean agent for critical electronics

CO2 – For non-occupied, enclosed electrical spaces

Inert Gases (Optional) – For special applications

All are non-conductive, equipment-safe, and environment-friendly.

Advanced indirect discharge technology

Instant detection through heat-sensing tube

Clean agent total flooding inside the rack

Does not release agent from the tube (safer and controlled)

No power or electronics required for activation

No false alarms or maintenance-heavy sensors

Fully automatic & self-contained

Uniform agent distribution across the rack

Highly reliable for high-value IT infrastructure

Data center server cabinets

Network & telecom racks

Edge computing enclosures

Cloud storage racks

UPS & battery backup racks

Modular IT racks

Sensitive electronics & switching racks

Broader suppression coverage than direct systems

Protects high-density racks and multi-rack clusters

Keeps IT equipment safe from fire and smoke

Reduces downtime and operational losses

No residue or cleanup required

Long-term reliable protection with minimal maintenance

Compatible with small, medium, and large server enclosures

Fire Engineering Technology is a leader in automatic tubing-based fire suppression systems, offering both DLP and ILP solutions.

Our systems are engineered with UL-approved tubing, precision nozzles, high-quality cylinders, and reliable clean agents—ensuring unmatched performance in critical IT environments.

We provide:

Custom design for every rack

Quick installation with no downtime

24×7 service and AMC support

Industry-best quality and durability

Want to know more about our products.. fill the form below