Fire Fighting system , Fire Safety Systems , Fire CO2 gas flooding systems , Fire Protection system , Fire Protection Systems , Fire Protection & Suppression Systems , Fire Suppression System , FIRE SUPPRESSION SYSTEM , Electrical Panels tube based automatic fire gas suppression system

27-Aug-2025

Fire suppression systems are critical for protecting people, equipment, and infrastructure from fire risks. Among the most reliable and compact solutions are low-pressure tube-based fire suppression systems, which are available in direct and indirect types.

This article explains Direct Low-Pressure vs Indirect Low-Pressure Suppression Technology, their working principle, benefits, applications, and FAQs.

A flexible heat-sensitive polymer detection tube is installed directly inside the equipment or enclosure.

When a fire starts, the tube ruptures at the hottest point.

The extinguishing agent (Clean Agent, CO2, or Dry Powder) is released directly at the fire source through the rupture.

Instant fire detection and suppression at the ignition point.

Simple and compact design (no nozzles or distribution piping required).

Lower installation and maintenance costs.

Works without electronics, sensors, or external power.

Ideal for electrical panels, CNC machines, server racks, and vehicles.

Electrical & MCC panels

DG sets and transformer panels

CNC and industrial machinery

Small enclosures, battery racks, and vehicles

The heat-sensitive detection tube is installed inside the equipment to sense fire.

When exposed to heat, the tube ruptures — but instead of discharging the agent from the rupture, it triggers a special release valve.

The extinguishing agent is then discharged through dedicated nozzles, covering the enclosure more uniformly.

Provides controlled discharge through designed nozzles.

Ensures wider coverage inside the enclosure.

Allows flexibility in nozzle placement for critical areas.

More agent efficiency since discharge is directed and distributed.

Ideal for larger enclosures or where fire could spread beyond a single point.

Larger electrical panels

Telecom racks and data servers

Battery energy storage systems (ESS)

Industrial control cabinets

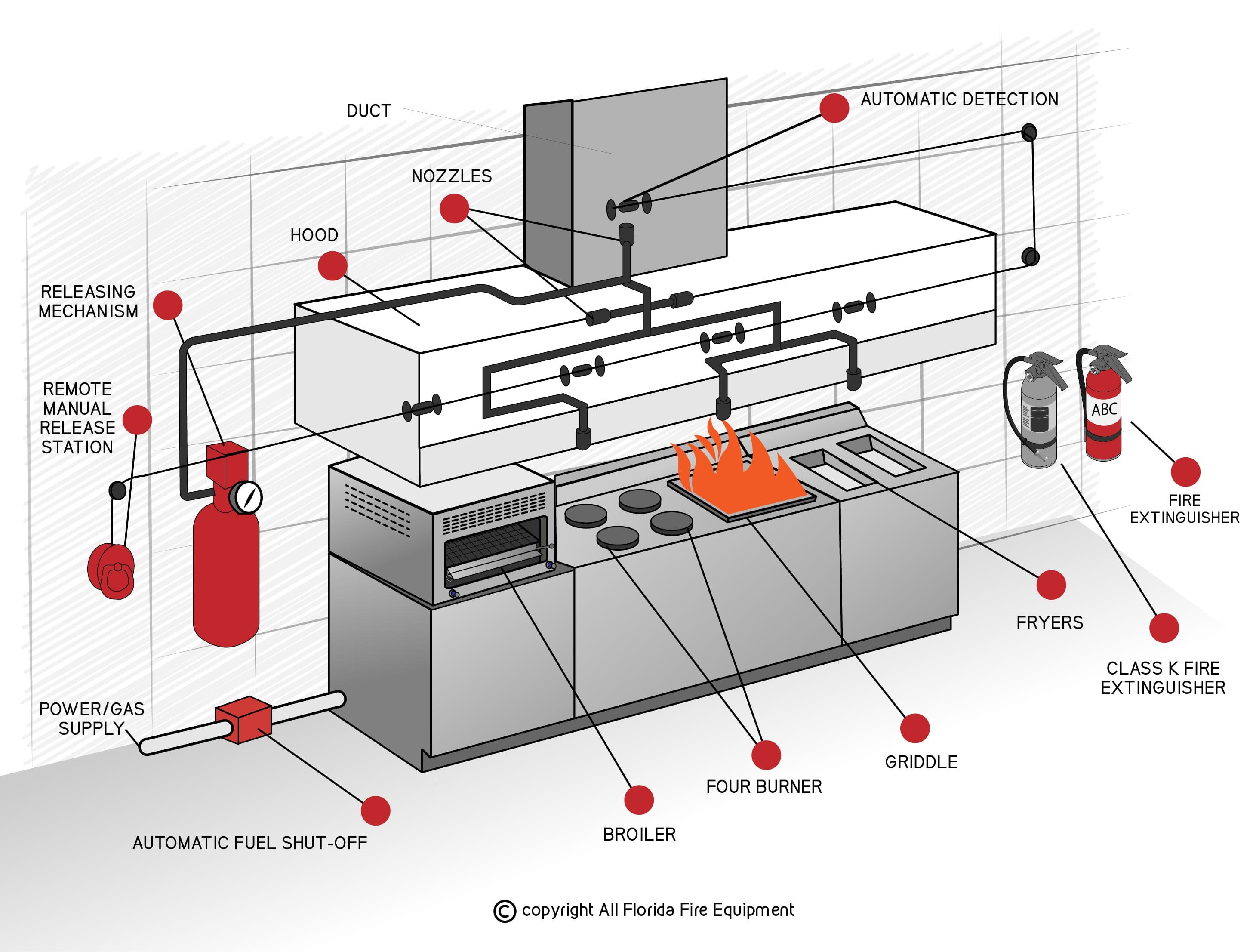

Commercial kitchens

| Feature | Direct Low-Pressure | Indirect Low-Pressure |

|---|---|---|

| Detection | Tube ruptures at fire source | Tube ruptures and activates valve |

| Discharge Point | At rupture point on tube | Through dedicated nozzles |

| Coverage | Localized, point-specific | Wider, enclosure-wide |

| Design Complexity | Very simple | Slightly complex (valves + nozzles) |

| Response Time | Instant | Slight delay (rupture → valve → nozzles) |

| Cost | Lower | Moderate |

| Best Applications | Small enclosures, panels, vehicles | Larger enclosures, telecom, ESS, kitchens |

? Works automatically without human intervention.

? No need for electrical detection systems.

? Compact and easy to retrofit.

? Safer for sensitive electronics (Clean Agents like FM200, NOVEC 1230).

? Cost-effective compared to total flooding systems.

Q1. What is the difference between direct and indirect low-pressure fire suppression?

Direct releases the extinguishing agent at the point of rupture, while indirect discharges it through nozzles for wider coverage.

Q2. Which system is better – direct or indirect?

Direct is best for small, localized enclosures, while indirect is suitable for larger enclosures requiring more controlled distribution.

Q3. Can both systems use clean agents?

Yes, both systems can work with Clean Agents (FM200, NOVEC 1230), CO2, or Dry Powder.

Q4. Is external power required for these systems?

No, both systems are mechanical and self-activating, requiring no power supply.

Q5. Where are direct low-pressure systems commonly used?

Electrical panels, CNC machines, DG sets, vehicles, and battery racks.

Q6. Where are indirect low-pressure systems commonly used?

Server racks, ESS, telecom equipment, commercial kitchens, and large industrial cabinets.

Q7. What is the cost difference between direct and indirect systems?

Direct systems are lower in cost due to their simpler design, while indirect systems cost slightly more due to valves and nozzle networks.

Q8. Do these systems require regular maintenance?

Yes, periodic inspection of the tube, pressure levels, and cylinder refilling is necessary.

Q9. Are these systems approved for industrial use?

Yes, they are widely accepted and certified under various fire safety standards.

Q10. Can direct and indirect systems be combined?

Yes, many industries use a combination: direct for small equipment and indirect for larger enclosures.

Both Direct and Indirect Low-Pressure Fire Suppression Systems are highly effective solutions for automatic fire protection.

If you need localized, instant suppression at the ignition point, choose Direct Low-Pressure.

If you need broader coverage inside a larger enclosure, choose Indirect Low-Pressure.

Many facilities use both technologies together, ensuring complete fire safety at both equipment and enclosure level.

Want to know more about our products.. fill the form below